FPD470

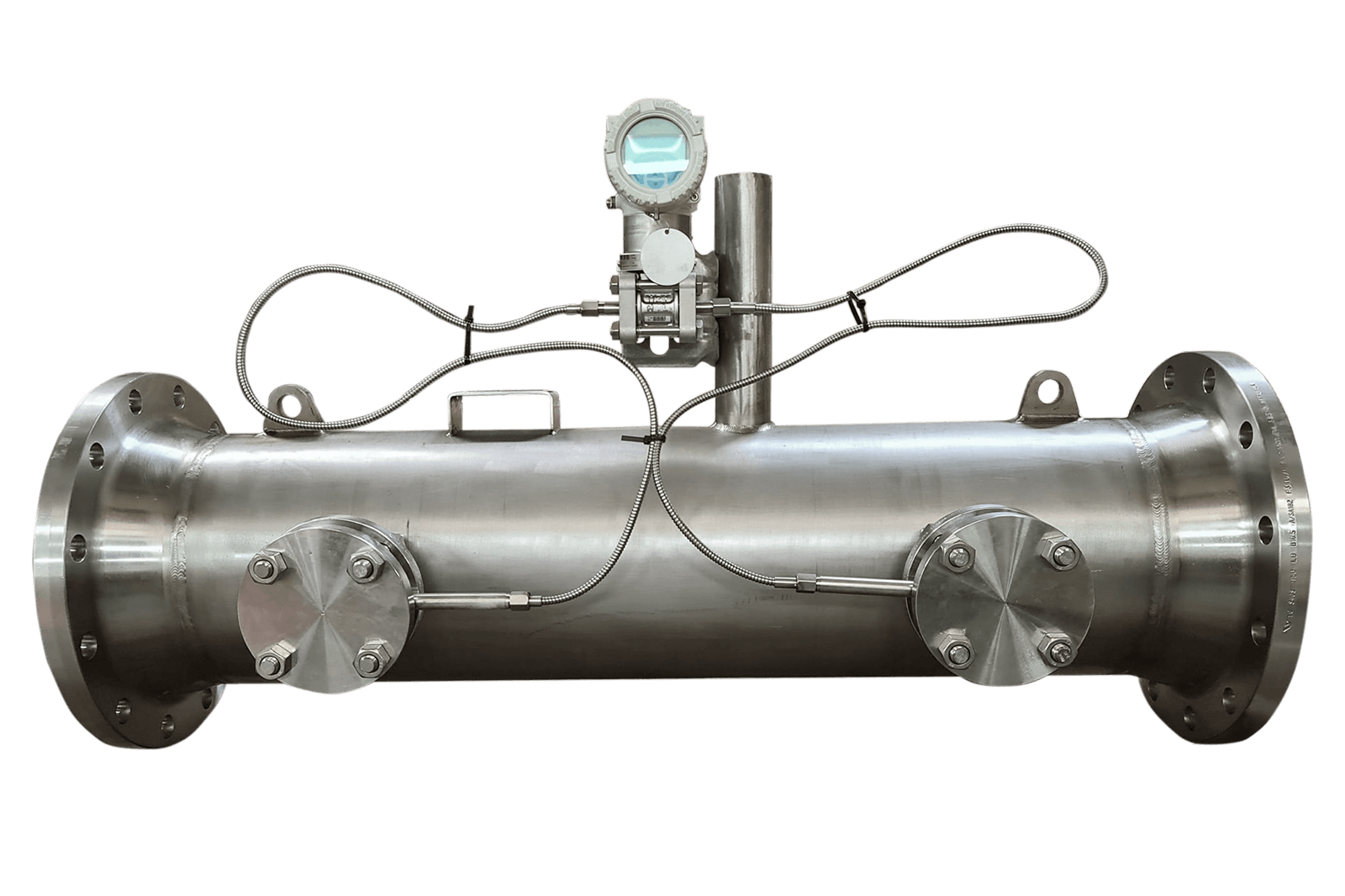

Wedge Flowmeter FPD470

Wedge Primary Element

Starting from:

$1,000.00

Categories:

A differential-pressure primary flow element featuring a V-shaped wedge restriction in the flow path. Its design is extremely robust and suited to bi-directional flow measurement, especially for fluids that are viscous, dirty, or slurry-laden.

The McMenon FPD470 is a robust wedge flow meter designed to perform in some of the toughest flow environments. Engineered to measure viscous fluids, slurry mixtures, or flow conditions with low Reynolds numbers, the FPD470 maintains accuracy where traditional differential pressure devices cannot.

With its solid one-piece wedge design and abrasion-resistant construction, the FPD470 offers excellent longevity and resistance to wear—even under harsh operating conditions. Compatible with corrosive fluids and particulate-laden streams, it’s ideal for upstream oil and gas, pulp and paper, and heavy process systems.

True to Eleven57’s mission, the FPD470 supports measurable progress in complex applications—offering durable instrumentation that enhances reliability, compliance, and operational equity in industries with demanding flow conditions.

Applications: viscous fluid monitoring, slurry transport, oil sands processing, mining operations, wastewater sludge control.

Specifications – FPD470 Wedge Flow Meter

Standard line sizes from ~0.5 in up to 24 in are available. It can measure liquids, gases, or steam at very low Reynolds numbers (down to ~500) due to the flow conditioning by the wedge. Achieves high accuracy (approximately ±0.5% of rate when calibrated) with minimal upstream/downstream straight-pipe requirements. The wedge element has no sharp edges to wear, ensuring measurement stability over time.

Pipe Sizes:

25 mm to 600 mm (1″ to 24″) standard; larger sizes available on request

Line Size Compatibility:

Matches nominal pipe size with custom designs for non-standard sizes

Process Connections:

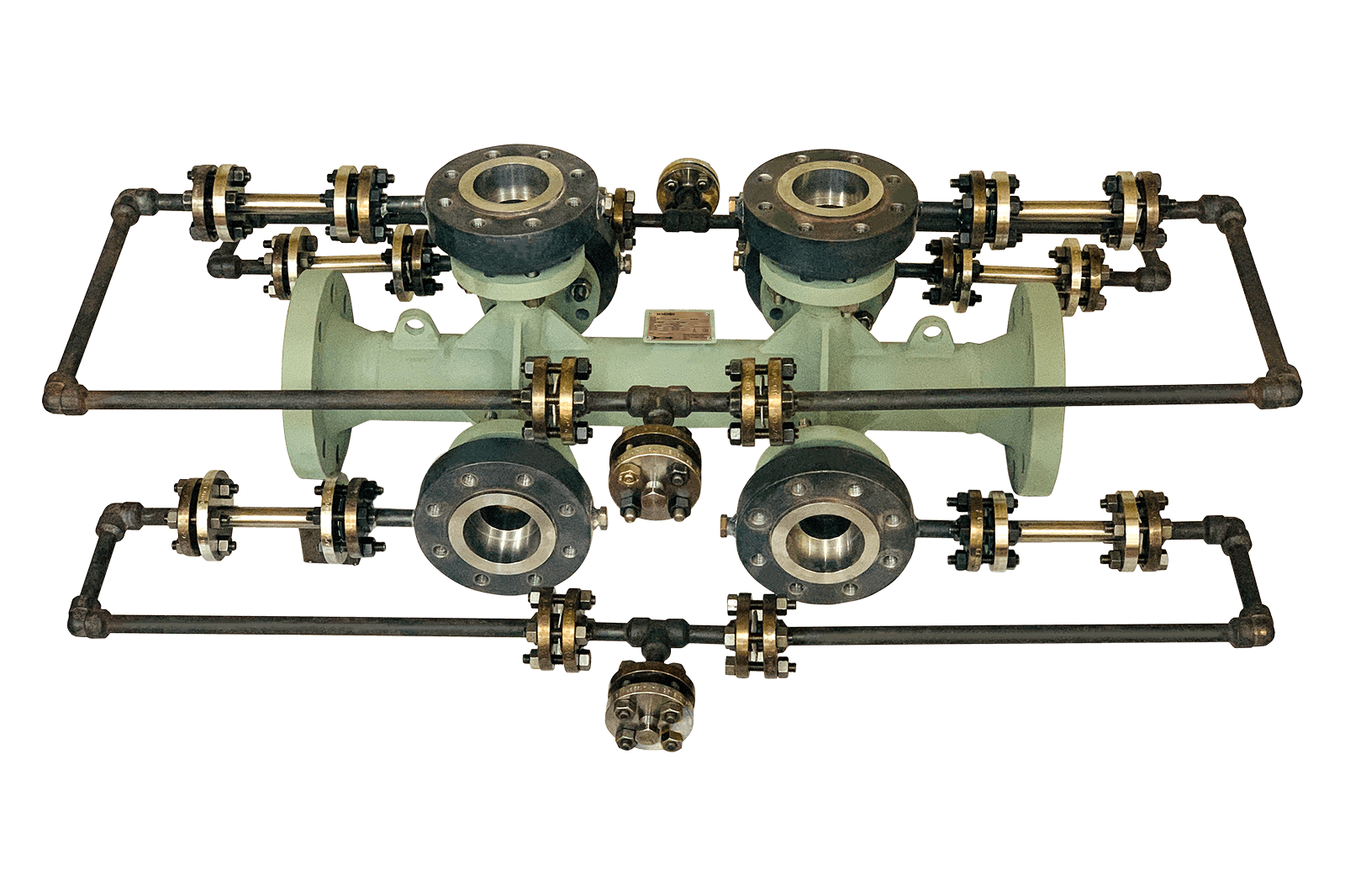

Flanged (ASME, ANSI, DIN, BS, JIS), wafer, or weld-end options

Pressure Ratings (Classes):

ANSI Class 150, 300, 600, 900, 1500, and 2500

Temperature Range:

Up to 815°C (1,500°F), depending on material and pressure class

Differential Pressure Range:

Customizable per application, typically 0–1000 inches H₂O

Turndown Ratio:

Up to 25:1 or more depending on transmitter and application

Reynolds Number Range:

Accurate down to Reynolds numbers below 500

Flow Media Compatibility:

Ideal for slurries, viscous fluids, dirty or abrasive liquids, and multiphase flows

Mounting Orientation:

Supports both horizontal and vertical installations

Body Materials:

Carbon steel, stainless steel (304, 316), Duplex, Hastelloy®, Monel®, and other alloys available upon request

Sealing/Gasket Options:

Graphite, PTFE, or custom-specified materials

Supporting Documents

Product data available (Wedge meter datasheet and manual) describing sizing, configurations (threaded or flanged connections, remote seals).

Industries & Solutions:

Well-suited for challenging fluids such as abrasive slurries, heavy oils, tar sands, or fluids with suspended solids where other DP elements would clog or wear. Common in oil & gas (e.g. asphalt, residuum flows) and chemical processes for its ability to handle thick, dirty flows with bi-directional capability.

- Oil sands and bitumen extraction

- Mineral and mining slurry pipeline

- Pulp and paper industry

- Petrochemical and refining

- Waste treatment and sludge management

Tools and Resources

Standard DP flow sizing software (e.g. SolveDP) can be used to size wedge meters; the vendor also provides configuration support for selecting proper wedge size and differential transmitter settings.