A6Q

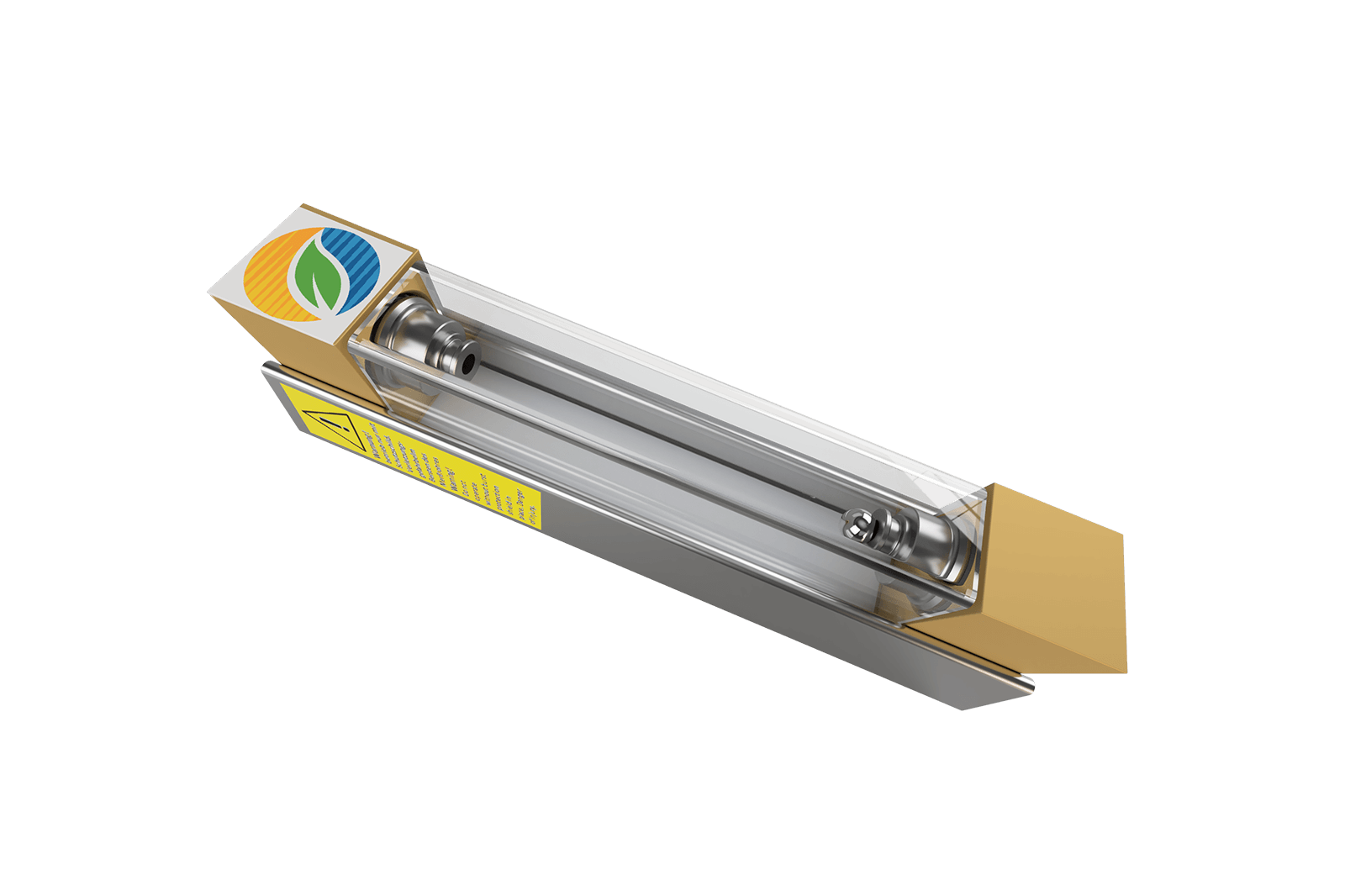

Glass Rotameter – Quick Ship A6

Glass Variable Area Flowmeter

Starting from:

$290.00

Categories:

The McMenon A6100 Series is a robust and compact glass tube variable area flowmeter designed for precise low flow measurement of gases and liquids in industrial applications. It is particularly suited for purge systems, sealing flows, instrumentation loops, and protective gas monitoring.

Engineered for high visibility and low maintenance, the A6 is panel-mount compatible and adaptable for OEM designs. Whether monitoring inert gases or maintaining seal flows, it supports Eleven57’s goal of delivering accessible, precision instrumentation that extends system performance and integrity.

Applications: instrument panel purge flow, seal water and air injection, protective gas regulation, sample line control.

Quick Ship covers a select subset of purge meter sizes, materials (often stainless steel fittings with borosilicate glass tube), and flow ranges that are frequently used. These units are pre-stocked or rapidly assembled to ship, typically in a few days. Technical specifications of the meters themselves are identical to the standard A6100/A6200 models – e.g. same pressure/temperature ratings and accuracy – but limited to the most broadly applicable options (e.g. standard floats, common connection types).

Features and Specifications.

Measures very low flows: for example, water ranges from approximately 0.01 to 74.4 fl oz/min (0.5 to 2200 cm³/min) and equivalent air flows, depending on the tube and float combination.

Mounting orientation is vertical (the float rises with flow); model A6100 has horizontal pipe connections (¼″ female NPT or BSPP) for in-line installation.

Maximum operating pressure: about 260 psi (~18 bar).

Maximum operating temperature: up to 248 °F (120 °C).

Scale lengths available: 1.5 in., 3 in., 5 in., or 10 in. (38, 76, 125, or 250 mm) for different reading resolutions.

Accuracy class: from ±1.6% to ±10% (at very low flows), depending on tube size.

Includes a corrosion-resistant stainless steel body, quick “snap-in” tube construction, and an impact protection shield.

- Tube diameter ranges from 1/8” to 1/4” (Other select sizes Available)

- Suitable for all transparent liquids and gases

- Accuracy classes from 2.5 to 10 % VDE/VDI

- Rangeability ≥10:1

- Flow and pressure control

- Snap-In Tube design

- Safety tested shields

- Interchangeable parts

- High & Low flow alarm

- High strength stainless steels & brass parts

- Easily installed

Supporting Documents

A catalog or flyer is provided listing the Quick Ship model codes and their details, indicating which A6 series configurations are included.

Solutions and Applications

This service is utilized when immediate replacement or installation of a purge flowmeter is needed, minimizing downtime. Industries such as laboratories, chemical plants, or OEM equipment manufacturers benefit from quick availability of these standard flowmeters for their gas or liquid purge lines.

Ideal for purging applications, instrument air/gas lines, or coolant flow monitoring where space is limited. Horizontal connection style eases installation in panel-mounted or skid-mounted systems with piping that runs laterally. Common uses: purging instrument enclosures, sample flow indication in analyzers, or low-flow chemical dosing lines.

- Low flow application in laboratory or field

- Purging line

- Fluid sampling line

- Low specific gravity

- Low flow inert gas line

- Coolant flow

- Gas Analyzers

- Air or water

Tools and Resources

Not applicable (program option rather than a separate tool) – standard selection tools apply to choose the meter, and qualifying models will be flagged as Quick Ship eligible by the vendor.

A sizing/selection tool is provided by the manufacturer for variable area flowmeters. It helps select the appropriate meter (tube/float) and indicates if a “quick ship” option is available for the chosen configuration.