Plant Gaseous Fuel Monitoring

Description of Application

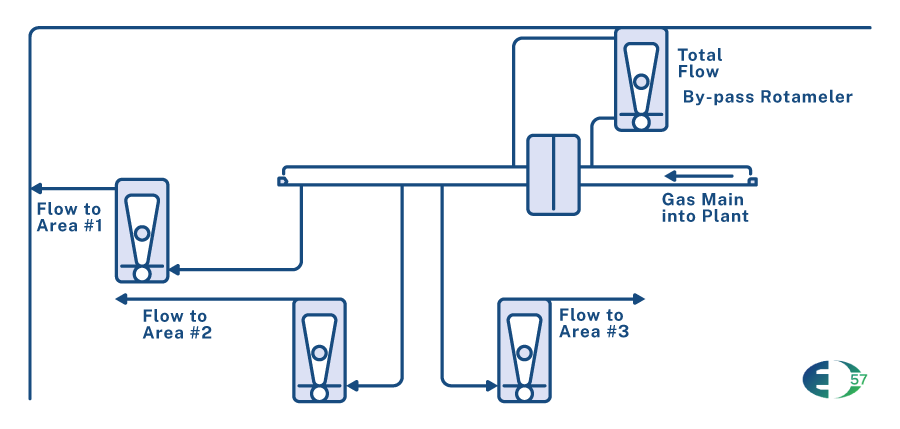

Plants that use large amounts of gaseous fuel, mostly Natural Gas, are constantly searching for ways to conserve energy, especially each time there is an increase in gas prices. In order to evaluate where efficiencies can be realized and gas saved, it is necessary to obtain usage figures (flow rates) for all areas or major users in the plant.

Used Where?

- Glass Product Manufacturing

- Industries that using large kilns and dryers(food, gran, lumber)

- Cement/lime plants

Method of Operation

Through-flow Rotameters or By-pass Rotameters can be used depending on flow rates. A permanent rotameter installation in each line affords easy monitoring of all flows at any time. If the gas flows are high enough and are to be checked infrequently (annually), it is possible to install an orifice plate in each line with a 1/2″ ball or gate valve on the orifice pressure taps and to use one meter to obtain the flow rates by connecting the meter to each set of orifice tap lines in turn. The meter scale must be graduated for the average line pressure and the readings corrected for pressure if it varies.

Model Selection

Use FGM11 with brass fittings or the customer may prefer stainless steel. If glass tubes are

unacceptable, use armored, 316 stainless steel Model FAM54 for indication.

Used How?