Cooling Water To Protect Heat Generating Equipment

Description of Application

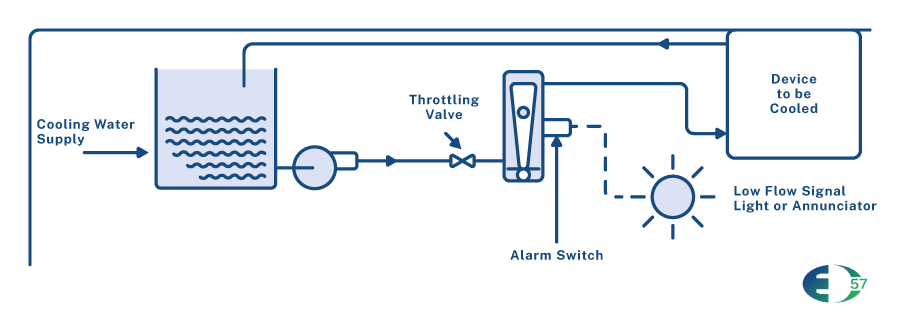

Certain types of electrical equipment require continuous cooling by circulation of cooling water to prevent thermal damage.

Used Where?

- OEM's Manufacturing electrical or machine tool equipment which requires cooling.

- Manufacturing Companies using large machine tools. OEM's

Method of Operation

The required amount of cooling water is easily set and monitored by the use of a Rotameter. If the heat load varies, resetting the cooling water flow is easily accomplished due to the inherently easy readability of the Rotameter scale. A low flow alarm switch set at a slightly lower than the normal flow rate gives an immediate warning of a decreasing total interruption of flow.

Model Selection

Since the required flow rate varies widely, different models/sizes will be required. The most widely used model is FAM2235 as an indicator only or with an attached low flow alarm. Brass/bronze may be used if the coolant is water. If greater scale resolution and accuracy are required, use Model FAM4555.

Rotameter Solution

The use of a Rotameter is the least expensive and most convenient way to set and monitor the flow of cooling

water.

Installed How?