FPD580

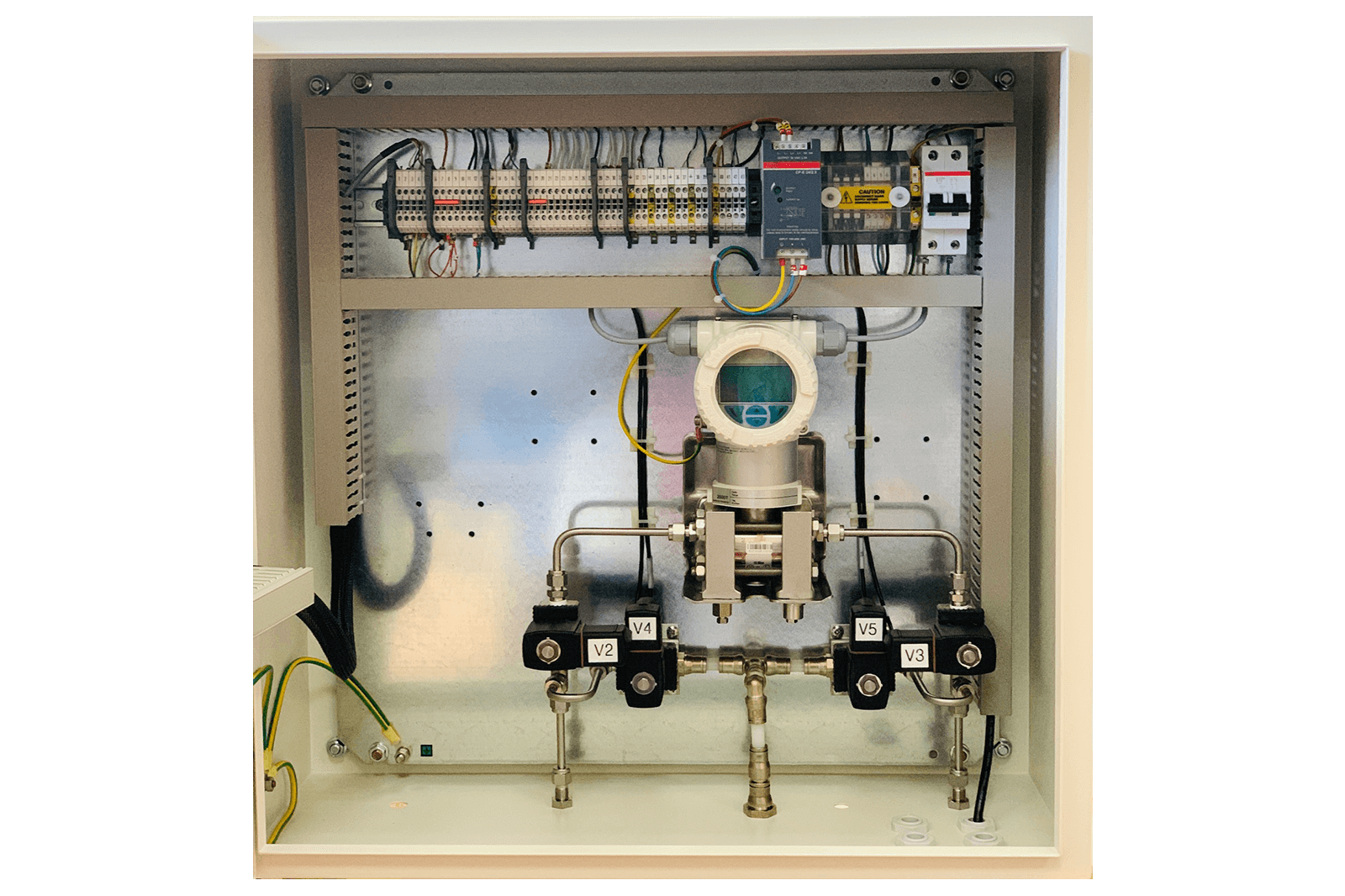

Emissions Monitoring Panel – Automatic system FPD585

FlowGenie

Starting from:

$8,500.00

Categories:

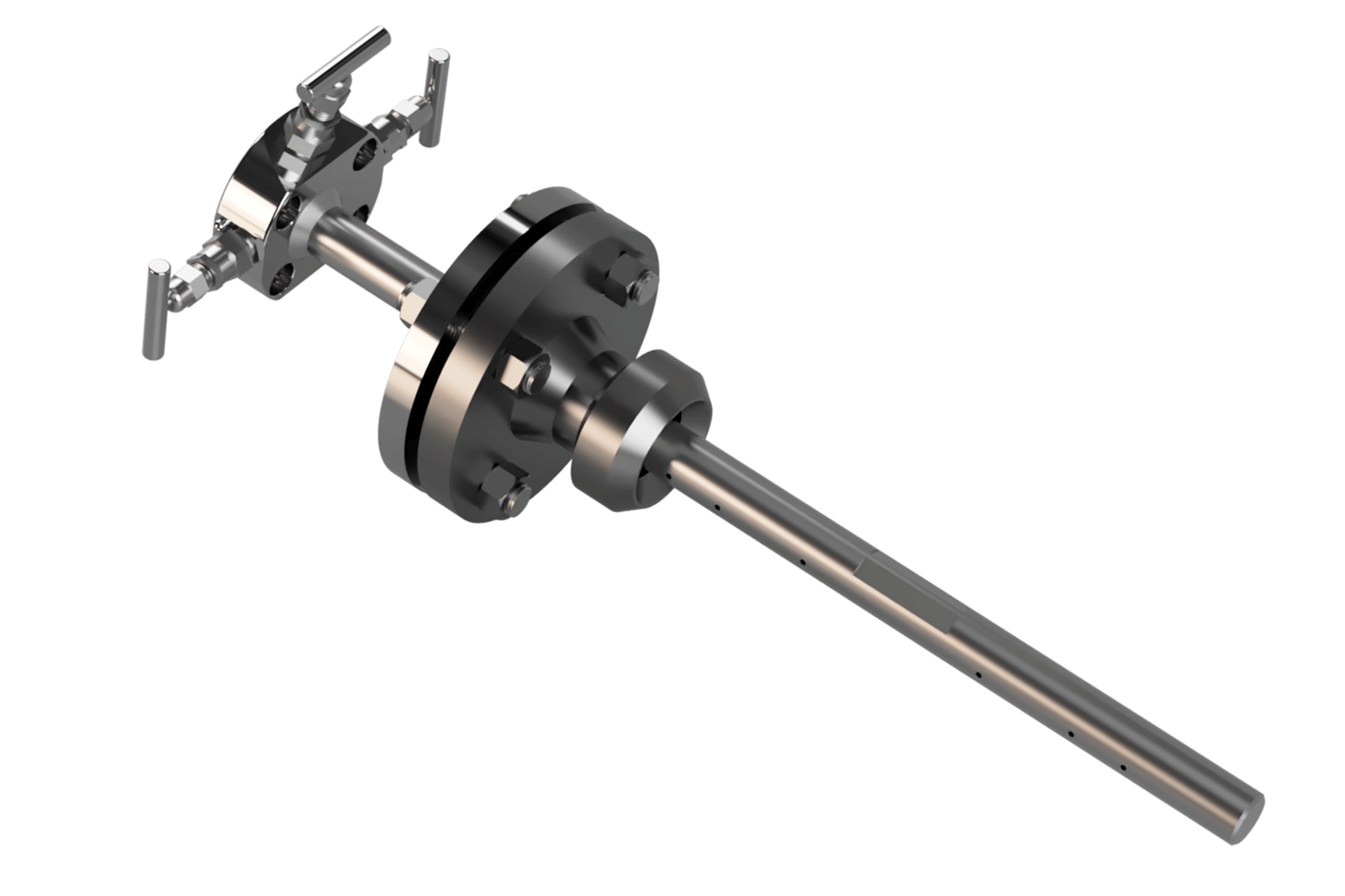

A complete stack gas flow monitoring system (StackFlowMaster) with automated purging and calibration checks. It uses an averaging pitot (Torbar) probe mounted in the stack and an electronic control unit to periodically purge the sensor and verify zero/span, ensuring reliable long-term operation in particulate-laden flue gas.

FPD585 – Intelligent Automation, Maximum Uptime

The FPD585 is Eleven57 Energy’s precision-engineered solution for continuous emissions monitoring in high-demand industrial environments. Featuring programmable purging and automatic zero/span calibrations, it minimizes maintenance while ensuring reliable, long-term performance—ideal for stacks with particulate concentrations up to 300 mg/m³.

Purpose-built for integration into modern CEMS packages, the FPD585 meets evolving regulatory expectations and is designed to align with future MCERTS certification standards.

Aligned with Eleven57’s mission to bring measurable, scalable solutions to global energy challenges, the FPD585 helps industrial operators maintain environmental compliance while improving system efficiency and data integrity.

Applications: emissions monitoring, compliance verification, industrial stack sampling, sustainability audits.

Includes the Torbar flow sensor (typically a 1″ or 2″ diameter probe spanning the stack) connected to an interface unit that handles automatic blowback purging for dust levels ~30–300 mg/m³. Purge duration and frequency are programmable to keep sensing holes clear of contaminants. Also features an automatic system zero/span check (periodic validation of the transmitter signal). MCERTS-certified (or similar) for regulatory use. The system can be configured with interface unit type B, C, or D, offering different I/O and redundancy options.

McMenon Emission FlowGenie – Product Specification Sheet

| Feature | FPD581 | FPD583 | FPD585 |

|---|---|---|---|

| Model Name | FPD581 | FPD583 | FPD585 |

| Compliance | No | EN 14181 / EN 15267-3 (MCERTS Certified) | Designed for MCERTS (Future Option) |

| System Type | Manual | Manual | Automatic |

| Purge Option | No | No | Yes |

| Zero/Span Check | No | No | Yes |

| MCERTS Certified | No | Yes | Future Option |

| Automation Level | None | Low (Manual Interface) | High (Automated Interface Unit) |

| Typical Use Case | Basic applications / probe replacement | Regulated industries requiring compliance | Automated, high-dust environments / remote operations |

| Stack Diameter Range | 1 to 8 meters (3.3 to 26.25 ft.) | 1 to 8 meters (3.3 to 26.25 ft.) | 1 to 8 meters (3.3 to 26.25 ft.) |

| Max Gas Temperature | Up to 1200°C (depends on material) | Up to 1200°C (depends on material) | Up to 1200°C (depends on material) |

| Max Particulate Load | N/A | Recommended up to 30 mg/m³ | Supports up to 300 mg/m³ |

| Output Options | Optional HART / Modbus | HART / Modbus | HART / Modbus / 4–20 mA |

| Transmitter Type | McMenon 267CS Multivariable | McMenon 267CS Multivariable | McMenon 267CS Multivariable |

| Display | Optional LCD | LCD (optional backlit) | Color TFT LCD display |

| Materials | 316L, 321H, or UNS N06625 Gr.2 stainless steel | 316L, 321H, or UNS N06625 Gr.2 stainless steel | 316L, 321H, or UNS N06625 Gr.2 stainless steel |

| Heater Option | No | Optional | Yes |

| Certifications | Optional (FM, CSA, others) | MCERTS, FM, CSA, TÜV | FM, CSA, TÜV (future option) |

Supporting Document

Detailed documentation is available (StackFlowMaster FPD581/583/585 manual) describing installation and operational parameters of the system.

Solutions:

Used for continuous emissions monitoring in stacks, particularly in coal-fired boilers, waste incinerators, or other processes with significant particulate in the flue gas. The FPD585 automatic system is ideal when manual maintenance is infrequent or impractical – it will self-clean and self-check, ensuring valid flow readings for regulatory reporting. It pairs with gas analyzers to form a complete CEMS solution monitoring pollutant mass emissions.

- Power generation facilities (coal, biomass, natural gas)

- Cement and aggregate processing plants

- Chemical and petrochemical manufacturing

- Steel mills and foundries

- Pulp and paper manufacturing

- Renewable energy systems with combustion processes

- Waste-to-energy and incineration sites

- Environmental compliance contractors and consultants

- Air quality monitoring and emissions verification services

Tools and Resources

No separate selection tool; the system is provided as a configured package. However, the manufacturer offers software/assistance to size the Torbar probe for the stack diameter and expected velocity range, and to set appropriate purge intervals.