FPD580

Emissions Monitoring Panel – Manual System FPD583

FlowGenie

Starting from:

$6,000.00

Categories:

Category Emissions Monitoring System

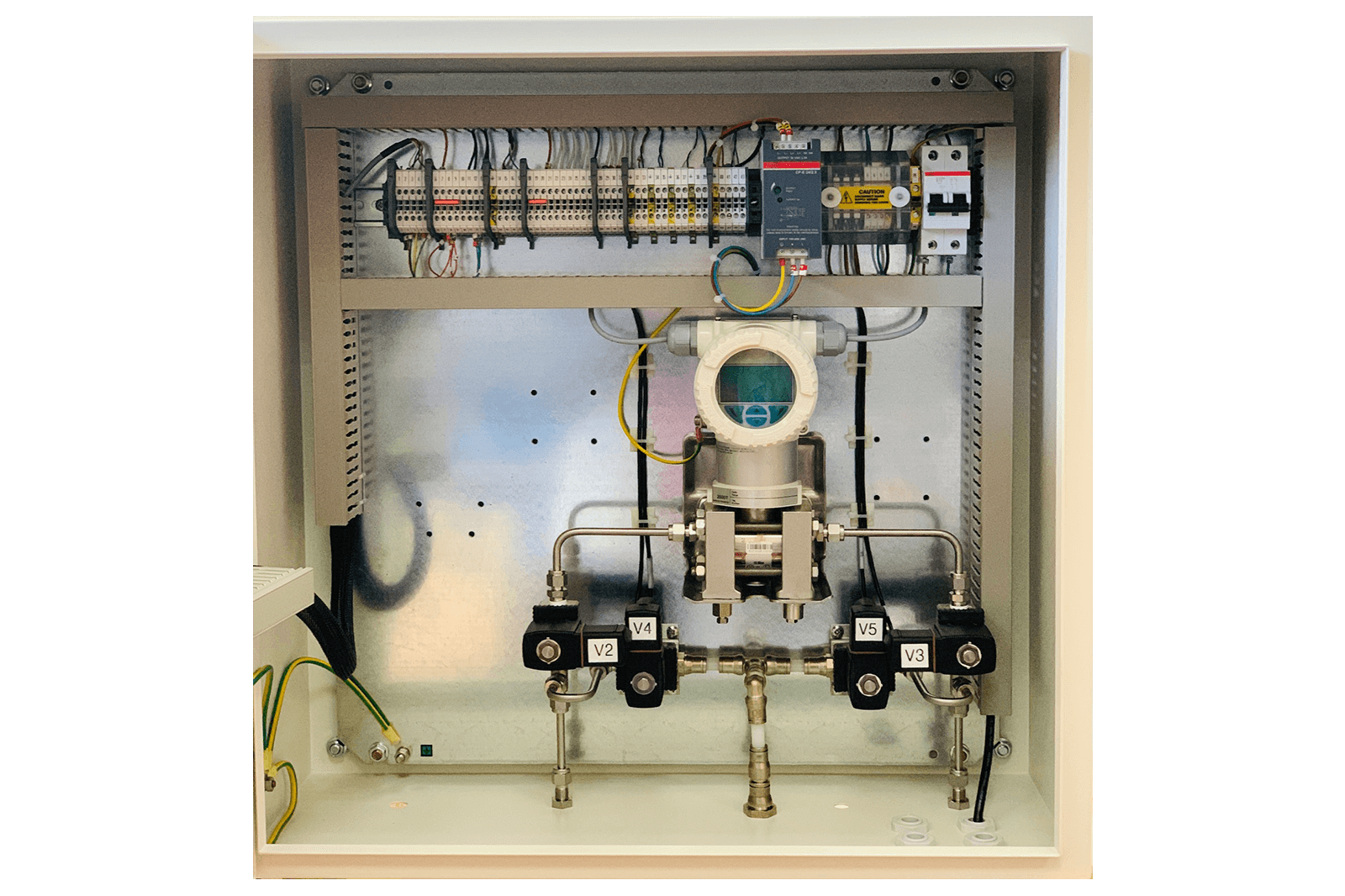

Semi-automated stack flow monitoring system with manual purge/maintenance, used for regulated emissions flow measurement in situations where full automation is not required or dust levels are sufficiently low to manage with periodic cleaning.

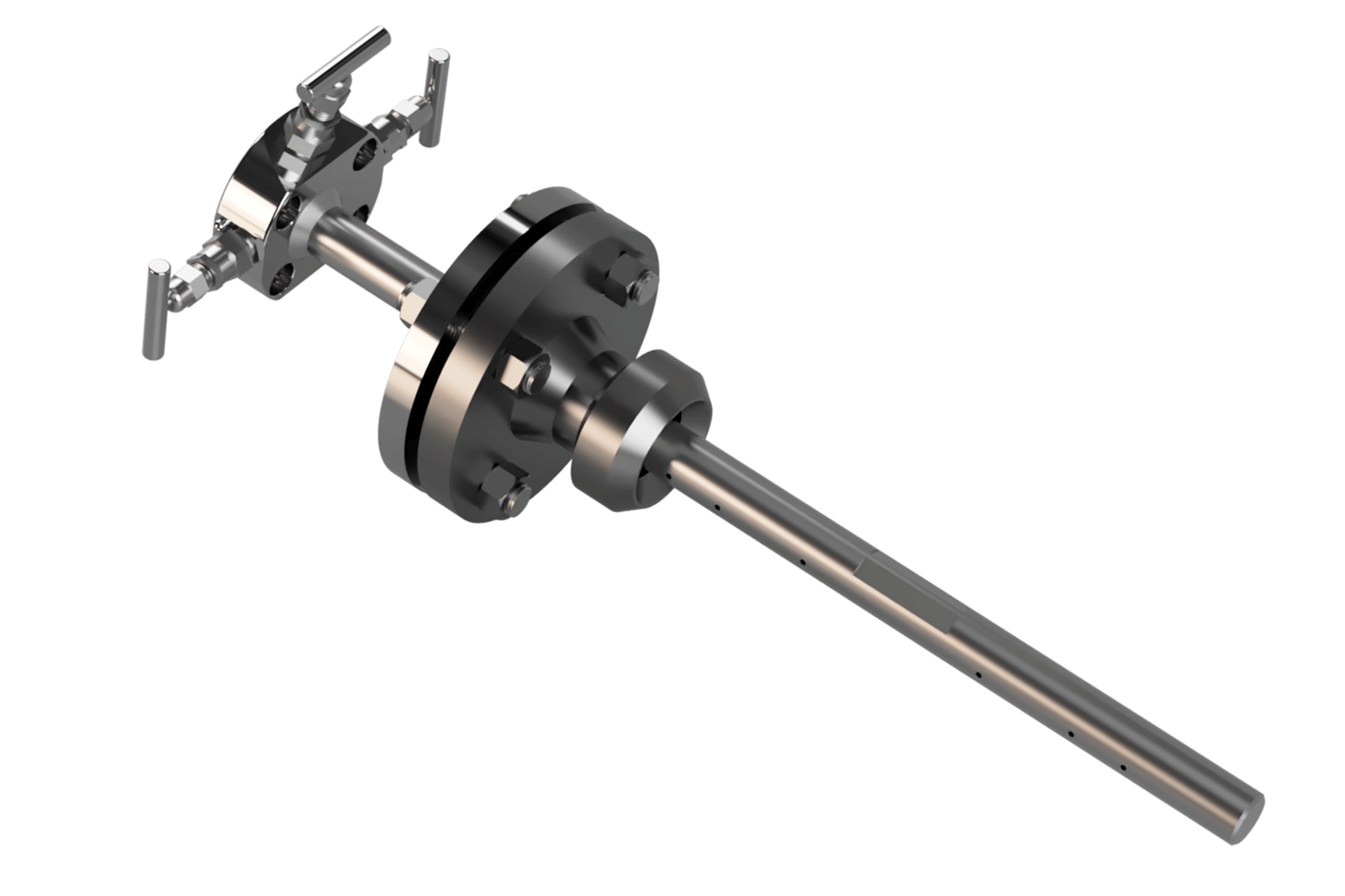

| A stack gas flow monitoring system similar to the automatic version but intended for manual or semi-automatic operation. It uses the same averaging pitot flow sensor but relies on manual purging (or periodic maintenance) rather than an automatic purge blower. Often supplied with certification (e.g. MCERTS) for regulatory monitoring. |

FPD583 – Certified Manual System for Compliance

The FPD583 delivers reliable stack emissions monitoring for facilities balancing performance and cost. Equipped with programmable purge functionality, it supports consistent accuracy in applications with moderate particulate levels.

While zero/span calibration remains a manual process, the FPD583 is CEMS-compatible and designed for integration into compliance frameworks across energy and industrial sectors. Built to support sustainability audits and regional air quality targets, it reflects Eleven57 Energy’s mission to expand access to measurable and scalable environmental instrumentation.

Applications: stack flow assessment, particulate emissions tracking, regional compliance auditing, baseline sampling.

| Comprises the Torbar averaging pitot probe, a DP transmitter (mounted on a 5-valve manifold either at the probe or remotely), and an interface unit “Manual A” for signal output. No active purge system is included – the sensor may be cleaned by plant personnel or by connecting an external air line occasionally. No automated zero/span calibration; the transmitter can be manually checked. Suitable for particle densities up to ~30 mg/m³ where fouling is slower. Provides the same flow measurement accuracy as the automated system when kept clean. |

McMenon Emission FlowGenie – Product Specification Sheet

| Feature | FPD581 | FPD583 | FPD585 |

|---|---|---|---|

| Model Name | FPD581 | FPD583 | FPD585 |

| Compliance | No | EN 14181 / EN 15267-3 (MCERTS Certified) | Designed for MCERTS (Future Option) |

| System Type | Manual | Manual | Automatic |

| Purge Option | No | No | Yes |

| Zero/Span Check | No | No | Yes |

| MCERTS Certified | No | Yes | Future Option |

| Automation Level | None | Low (Manual Interface) | High (Automated Interface Unit) |

| Typical Use Case | Basic applications / probe replacement | Regulated industries requiring compliance | Automated, high-dust environments / remote operations |

| Stack Diameter Range | 1 to 8 meters (3.3 to 26.25 ft.) | 1 to 8 meters (3.3 to 26.25 ft.) | 1 to 8 meters (3.3 to 26.25 ft.) |

| Max Gas Temperature | Up to 1200°C (depends on material) | Up to 1200°C (depends on material) | Up to 1200°C (depends on material) |

| Max Particulate Load | N/A | Recommended up to 30 mg/m³ | Supports up to 300 mg/m³ |

| Output Options | Optional HART / Modbus | HART / Modbus | HART / Modbus / 4–20 mA |

| Transmitter Type | McMenon 267CS Multivariable | McMenon 267CS Multivariable | McMenon 267CS Multivariable |

| Display | Optional LCD | LCD (optional backlit) | Color TFT LCD display |

| Materials | 316L, 321H, or UNS N06625 Gr.2 stainless steel | 316L, 321H, or UNS N06625 Gr.2 stainless steel | 316L, 321H, or UNS N06625 Gr.2 stainless steel |

| Heater Option | No | Optional | Yes |

| Certifications | Optional (FM, CSA, others) | MCERTS, FM, CSA, TÜV | FM, CSA, TÜV (future option) |

Supporting Document

| System documentation (StackFlowMaster series) covers the configuration and maintenance of the manual system and its operation. |

Industries & Solutions:

| Used in emissions monitoring where flue gas dust loading is low or where operators can perform regular probe maintenance. Examples: natural gas-fired plant stacks (low particulate) or smaller boilers. The FPD583 offers a cost-effective solution for compliant flow monitoring as long as manual purging (or periodic probe replacement/cleaning) is manageable. |

- Power generation facilities (coal, biomass, natural gas)

- Cement and aggregate processing plants

- Chemical and petrochemical manufacturing

- Steel mills and foundries

- Pulp and paper manufacturing

- Renewable energy systems with combustion processes

- Waste-to-energy and incineration sites

- Environmental compliance contractors and consultants

- Air quality monitoring and emissions verification services

Tools and Resources

| No special selection tool beyond specifying stack diameter and expected flow range to size the Torbar probe. The system is configured by the vendor; operators follow maintenance guidelines to keep it functional (the vendor provides support and flow calibration data for setup). |