A6

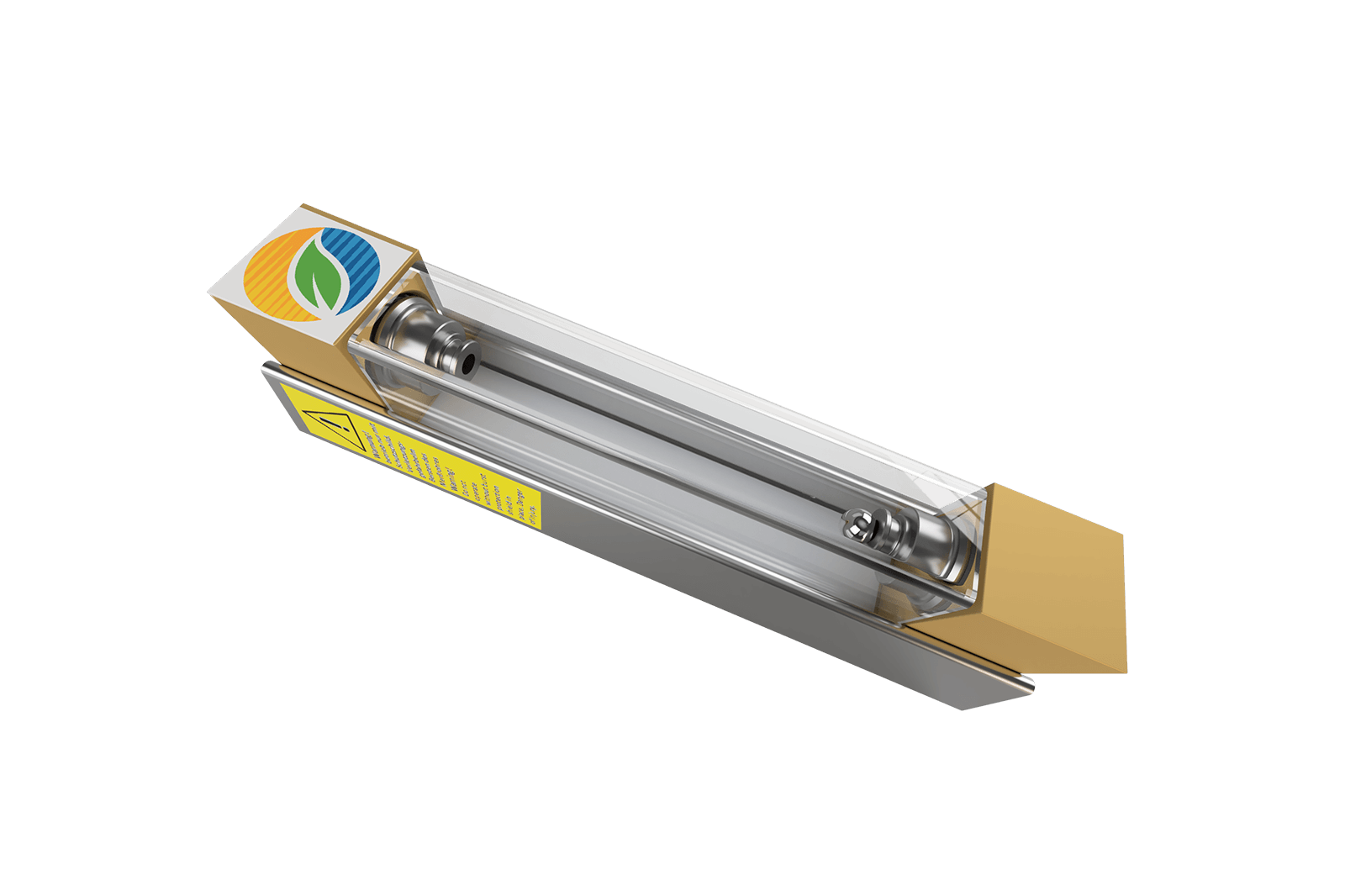

Glass Rotameter – Vertical Connection A6200

Glass Variable Area Flowmeter

Starting from:

$290.00

Categories:

The McMenon A6 is a highly reliable purge-style variable area flowmeter designed for low-volume liquid or gas measurement. With its clear, direct-read scale and compact build, the A6 excels in applications requiring steady flow control at low pressure—especially for purging, sealing, and instrumentation loops.

Engineered for high visibility and low maintenance, the A6 is panel-mount compatible and adaptable for OEM designs. Whether monitoring inert gases or maintaining seal flows, it supports Eleven57’s goal of delivering accessible, precision instrumentation that extends system performance and integrity.

Applications: instrument panel purge flow, seal water and air injection, protective gas regulation, sample line control.

Features and Specifications

Covers the same flow ranges as the horizontal version (water ~0.5 to 2200 cm³/min, air flows in similar low ranges). The A6200 model has vertical connections (¼″ NPT/BSPP) on the bottom and top, suited for inline vertical piping. Operating limits: up to 18 bar and 120 °C. Available in multiple scale lengths (short to long) to trade off size vs. reading resolution. Accuracy falls in the ±1.6% – ±10% range depending on flow range (better accuracy on larger flows). All Purgemaster units include a stainless steel body, quick snap-in tube assembly, and integral safety shield for the glass tube.

- Tube diameter ranges from 1/8” to 1/4” (Other select sizes Available)

- Suitable for all transparent liquids and gases

- Accuracy classes from 2.5 to 10 % VDE/VDI

- Rangeability ≥10:1

- Flow and pressure control

- Snap-In Tube design

- Safety tested shields

- Interchangeable parts

- High & Low flow alarm

- High strength stainless steels & brass parts

- Easily installed

Supporting Documents

Product documentation (Models A6100 & A6200 data sheet) provides full specifications and flow tables for each configuration.

Solutions and Applications

Well-suited for panel-mounted flow indication in labs or skid systems, especially where vertical flow orientation is required. Common uses: purge flows to process instruments, carrier gas flows in analytical equipment, and any low-flow metering in water treatment or chemical injection systems. The vertical connection configuration facilitates direct inline installation in a vertical run of tubing or piping.

- Purging line|

- Fluid sampling line

- Low specific gravity

- Low flow inert gas line

- Coolant flow

- Gas Analyzers

- Air or water

- Analytical systems and gas panels

- Pump Seal support applications

- OEM low-flow assemblies

- Chemical and utility flow management

Tools and Resources

The manufacturer’s selection tool covers both horizontal and vertical variants, assisting in choosing the correct float/tube and showing if the configuration is part of the quick-ship program.