FPD350

H8 McMenon Averaging Pitot Flowmeter FPD350

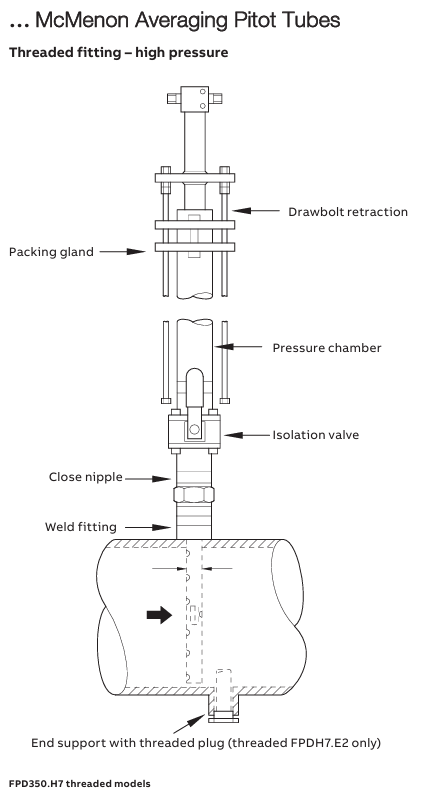

Averaging Pitot Tube - Standard Diameter Probe - Hot Tap : High Pressure

Starting from:

$0.00

Categories:

The FPD350 H8 is designed for critical environments where high pressure and temperature conditions demand uncompromising accuracy and durability. Built with reinforced materials and optimized for steady-state flow, it supports mission-critical industrial processes across the energy sector.

An extreme-service averaging pitot tube flowmeter capable of measuring flow under very harsh conditions (potentially high-pressure drop, highly erosive, or ultra-high temperature environments). It averages the impact pressure across multiple ports, providing a stable DP output for flow with minimal blockage and pressure loss.

Engineered with reinforced construction and possibly exotic materials or coatings to resist corrosion/erosion. Covers a broad pipe size range, typically incorporating threaded or flanged mounting with welded reinforcement as needed. Provides accurate measurements across a wide flow range with low sensitivity to upstream disturbances. Accuracy on par with standard models (around ±1%) and excellent repeatability. Designed and tested to ensure it can withstand the target process conditions (including vibration and erosion).

McMenon FPD350 Averaging Pitot Tube – Comprehensive Specifications

Measurement Type:

- Multiport self-averaging flow measurement for gases, liquids, and steam

Pipe Size Range:

- 10 mm to 8000 mm (0.4 in. to 315 in.)

Pressure Ratings:

- Threaded Models (FPD350.T3/T4/H6/H7): Up to 50 bar (725 psi) at 400 °C (752 °F)

- Flanged Models (FPD350.T5/H8):Up to ANSI Class 2500 (1450 psi)

- Hot-Tap Models (FPD350.L7/H7/H8):Up to 10 bar (145 psi) with gate valve, 40 bar (580 psi) with ball valve

Temperature Ratings:

- Threaded Models: Up to 400 °C (752 °F)

- Flanged Models: Up to 450 °C (840 °F)

- Hot-Tap Models: Up to 400 °C (752 °F)

Accuracy and Repeatability:

- Accuracy: ±1% of reading (when installed as per guidelines)

- Repeatability: ±0.5% of reading

Flow Turndown Ratios:

- Standard models: Up to 10:1

- High turndown versions available for specific applications

Connection Types:

- Threaded (BSPT/NPT): 1/4 in., 3/8 in., 1/2 in., 1 in., 1.5 in., 2 in.

- Flanged (ANSI/DIN): DN 15 to DN 3500

Construction Materials:

- 316/316L Stainless Steel (S6)

- 304/304L Stainless Steel (S4)

- 321/321H Stainless Steel (S2)

- Alloy C276 (U7)

- Alloy 400 (M4)

- Alloy 625 (N2)

- 22% Cr Duplex (D1)

- 25% Cr Super Duplex (D2/D3)

- 6% Mo SS (M1)

Valve Options:

- Isolation Valves: Ball, gate, and globe valves available

- Connection Sizes: 1/4 in. to 3 in.

- Valve Materials: Carbon steel, 316SS, Alloy 400, Alloy C276

End Support Options:

- Threaded End Support

- Flanged End Support

- Weld Cup End Support

- Gear Retract Mechanism for hot-tap models

Process Isolation Valves:

- Sizes: 1/2 in., 3/4 in., 1 in., 1.5 in., 2 in., 3 in.

- Material Options: 316SS, Alloy 400, Alloy C276

- Pressure Ratings: Up to 100 bar (1450 psi)

Temperature Elements (Optional):

- Integral PT100 sensor, neck-mounted (4-20 mA output)

- Integral Type K thermocouple sensor

- Pressure Rating: Up to 70 bar (1015 psi)

Additional Accessories:

- Air Eliminators

- Condensate Pots (Carbon Steel or 316SS)

- Frequency Collars

- Gear Retraction Assemblies

- Bi-directional Probe Configuration

Certifications and Compliance:

- EN 10204 3.1 / 3.2 Material Certificates

- NACE MR 0175/ISO 15156 for corrosion resistance

- Pressure Testing and Positive Material Identification (PMI)

- Radiography and Dye Penetrant Inspection (DPI)

Electrical Output Options:

- Analog Output: 4-20 mA, 2-wire

- Alarm Signaling: Min/Max Alarm Units

- Electrical Connections: NPT or BSPT, cable lengths available upon request

Installation Orientation:

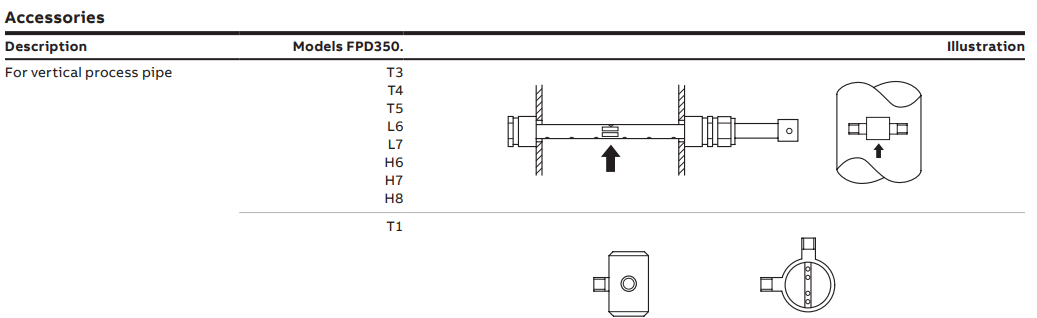

- Horizontal or vertical installation

- Compatible with circular and rectangular pipes/ducts

Special Options:

- Partial Insertion Probe

- Gear Retract for Hot-Tap Applications

- Special Neck Lengths and Custom Fittings

Supporting Documents

Detailed specifications are included in the FPD350 series documentation, which highlights options for different pressure classes and temperature ratings in the H-series variants.

Industries & Solutions:

Appropriate for tough flow measurement tasks such as catalyst slurry flows, high-pressure feedstocks, or other situations where conventional flowmeters would be prone to damage or cause too much pressure drop. The H-series averaging pitot can handle abrasive or high-energy flows (e.g., fluids with solid particles or very hot gases) while providing stable readings and long service life.

- Thermal power plants (coal, combined cycle)

- Upstream and midstream oil & gas operations

- Petrochemical and refining operations

- High-pressure steam networks

- Industrial process heat systems

Tools and Resources

Sizing and application engineering support are available from the manufacturer to tailor the device to these challenging scenarios (including verifying structural integrity via specialized calculations).