FPD350

T4 McMenon Averaging Pitot Flowmeter FPD350

Averaging Pitot Tube - Standard Diameter Probe

Starting from:

$2,300.00

Categories:

Averaging pitot tube flowmeter featuring multiple sensing ports to obtain an average flow velocity, thereby enabling accurate differential-pressure-based flow measurement with negligible pressure loss.

The FPD350 T4 is an energy-balanced flowmeter designed to manage and monitor thermal distribution in commercial and industrial systems. Supporting hydronic heating, district cooling, and thermal energy metering, it helps improve building-level efficiency and thermal accountability.

With a compact design and calibration stability, the T4 aligns with Eleven57’s energy equity mission—helping reduce thermal waste and support infrastructure upgrades in legacy or emerging energy grids.

Applications: HVAC optimization, building thermal management, chilled water metering, district energy efficiency.

Applicable to line sizes from small pipes to large stacks (with model selection). Typically achieves 1% or better flow accuracy after calibration. Handles fluid temperatures and pressures per standard pipe ratings since the probe is inserted into the flow. Provides 10:1 (or greater) flow turndown. Can be installed permanently via flanged or compression fittings, or as a retractable unit for maintenance. Made from robust materials to withstand industrial environments.

McMenon FPD350 Averaging Pitot Tube – Comprehensive Specifications

Measurement Type:

Multiport self-averaging flow measurement for gases, liquids, and steam

Pipe Size Range:

10 mm to 8000 mm (0.4 in. to 315 in.)

Pressure Ratings:

Threaded Models (FPD350.T3/T4/H6/H7): Up to 50 bar (725 psi) at 400 °C (752 °F)

Flanged Models (FPD350.T5/H8):Up to ANSI Class 2500 (1450 psi)

Hot-Tap Models (FPD350.L7/H7/H8):Up to 10 bar (145 psi) with gate valve, 40 bar (580 psi) with ball valve

Temperature Ratings:

Threaded Models: Up to 400 °C (752 °F)

Flanged Models: Up to 450 °C (840 °F)

Hot-Tap Models: Up to 400 °C (752 °F)

Accuracy and Repeatability:

Accuracy: ±1% of reading (when installed as per guidelines)

Repeatability: ±0.5% of reading

Flow Turndown Ratios:

Standard models: Up to 10:1

High turndown versions available for specific applications

Connection Types:

Threaded (BSPT/NPT): 1/4 in., 3/8 in., 1/2 in., 1 in., 1.5 in., 2 in.

Flanged (ANSI/DIN): DN 15 to DN 3500

Construction Materials:

316/316L Stainless Steel (S6)

304/304L Stainless Steel (S4)

321/321H Stainless Steel (S2)

Alloy C276 (U7)

Alloy 400 (M4)

Alloy 625 (N2)

22% Cr Duplex (D1)

25% Cr Super Duplex (D2/D3)

6% Mo SS (M1)

Valve Options:

Isolation Valves: Ball, gate, and globe valves available

Connection Sizes: 1/4 in. to 3 in.

Valve Materials: Carbon steel, 316SS, Alloy 400, Alloy C276

End Support Options:

Threaded End Support

Flanged End Support

Weld Cup End Support

Gear Retract Mechanism for hot-tap models

Process Isolation Valves:

Sizes: 1/2 in., 3/4 in., 1 in., 1.5 in., 2 in., 3 in.

Material Options: 316SS, Alloy 400, Alloy C276

Pressure Ratings: Up to 100 bar (1450 psi)

Temperature Elements (Optional):

Integral PT100 sensor, neck-mounted (4-20 mA output)

Integral Type K thermocouple sensor

Pressure Rating: Up to 70 bar (1015 psi)

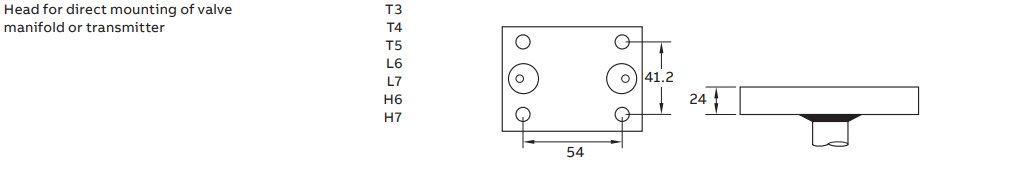

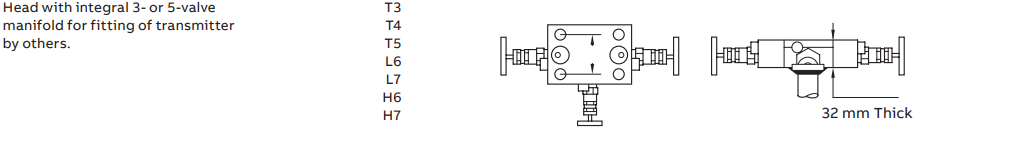

Additional Accessories:

Air Eliminators

Condensate Pots (Carbon Steel or 316SS)

Frequency Collars

Gear Retraction Assemblies

Bi-directional Probe Configuration

Certifications and Compliance:

EN 10204 3.1 / 3.2 Material Certificates

NACE MR 0175/ISO 15156 for corrosion resistance

Pressure Testing and Positive Material Identification (PMI)

Radiography and Dye Penetrant Inspection (DPI)

Electrical Output Options:

Analog Output: 4-20 mA, 2-wire

Alarm Signaling: Min/Max Alarm Units

Electrical Connections: NPT or BSPT, cable lengths available upon request

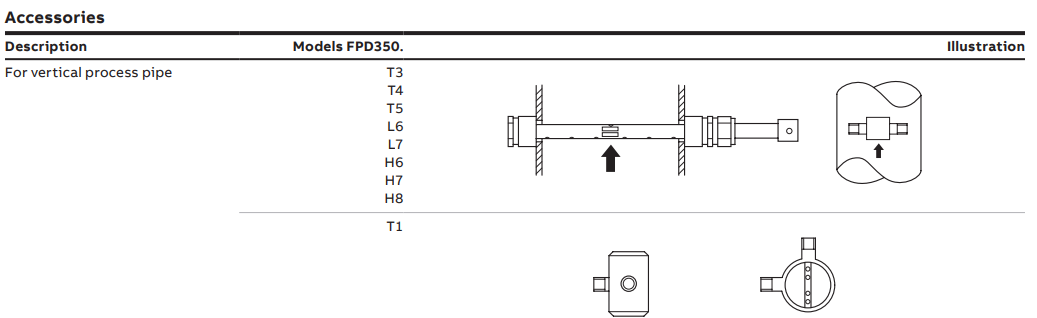

Installation Orientation:

Horizontal or vertical installation

Compatible with circular and rectangular pipes/ducts

Special Options:

Partial Insertion Probe

Gear Retract for Hot-Tap Applications

Special Neck Lengths and Custom Fittings

Supporting Documents

Often used for flow measurements in utilities and process industries: examples include plant air flow, heater exhaust flow, cooling water, and other applications where low maintenance and low pressure drop are priorities. Its ability to be installed without large pressure recovery losses makes it ideal for energy management systems and large diameter flow measurements.

Manufacturer datasheets detail the design and performance of the Torbar/averaging pitot (FPD350) including pressure ratings and support requirements.

Industries & Solutions:

- District heating and cooling utilities

- Commercial HVAC contractors and designers

- Government and university campus infrastructure

- Smart building and energy metering solutions

- Data center cooling optimization

Tools and Resources

The manufacturer’s selection tool is available to configure the pitot tube and calculate expected differential pressures for given flow conditions.