FPD350

T5 McMenon Averaging Pitot Flowmeter FPD350

Averaging Pitot Tube - 2" Diameter Probe

Starting from:

$2,300.00

Categories:

A multi-point averaging pitot flowmeter designed to measure flow by sampling at several points across the pipe, yielding an averaged differential pressure signal proportional to flow. It provides stable readings and low permanent pressure loss.

The FPD350 T5 delivers reliable differential pressure flow measurement for a broad range of process conditions. With modular adaptability and strong repeatability, it suits continuous improvement programs and industrial upgrades across multiple verticals.

Built with Eleven57’s commitment to scalable, measurable instrumentation, the T5 supports balance-of-plant monitoring, cost reduction initiatives, and environmental data collection.

Applications: water/steam flow, chemical batching, mid-pressure process control, sustainability compliance initiatives.

McMenon FPD350 Averaging Pitot Tube – Comprehensive Specifications

Covers pipe diameters from roughly 2″ up to very large conduits; available in custom lengths and mounting configurations. Features bi-directional measurement capability (if required) and performs well at low Reynolds numbers (good for viscous flows). Typical accuracy ~±1% of flow (with calibration) and repeatability better than 0.2%. The sensor has no moving parts and requires minimal straight-run (generally a few pipe diameters) due to the flow averaging effect.

Measurement Type:

- Multiport self-averaging flow measurement for gases, liquids, and steam

Pipe Size Range:

- 10 mm to 8000 mm (0.4 in. to 315 in.)

Pressure Ratings:

- Threaded Models (FPD350.T3/T4/H6/H7): Up to 50 bar (725 psi) at 400 °C (752 °F)

- Flanged Models (FPD350.T5/H8):Up to ANSI Class 2500 (1450 psi)

- Hot-Tap Models (FPD350.L7/H7/H8):Up to 10 bar (145 psi) with gate valve, 40 bar (580 psi) with ball valve

Temperature Ratings:

- Threaded Models: Up to 400 °C (752 °F)

- Flanged Models: Up to 450 °C (840 °F)

- Hot-Tap Models: Up to 400 °C (752 °F)

Accuracy and Repeatability:

- Accuracy: ±1% of reading (when installed as per guidelines)

- Repeatability: ±0.5% of reading

Flow Turndown Ratios:

- Standard models: Up to 10:1

- High turndown versions available for specific applications

Connection Types:

- Threaded (BSPT/NPT): 1/4 in., 3/8 in., 1/2 in., 1 in., 1.5 in., 2 in.

- Flanged (ANSI/DIN): DN 15 to DN 3500

Construction Materials:

- 316/316L Stainless Steel (S6)

- 304/304L Stainless Steel (S4)

- 321/321H Stainless Steel (S2)

- Alloy C276 (U7)

- Alloy 400 (M4)

- Alloy 625 (N2)

- 22% Cr Duplex (D1)

- 25% Cr Super Duplex (D2/D3)

- 6% Mo SS (M1)

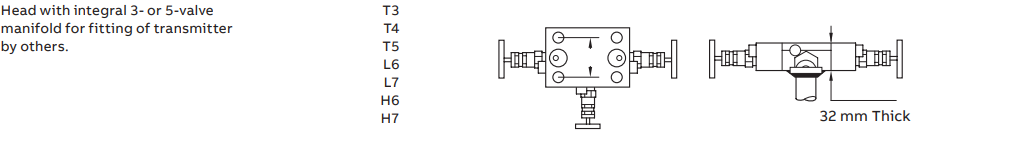

Valve Options:

- Isolation Valves: Ball, gate, and globe valves available

- Connection Sizes: 1/4 in. to 3 in.

- Valve Materials: Carbon steel, 316SS, Alloy 400, Alloy C276

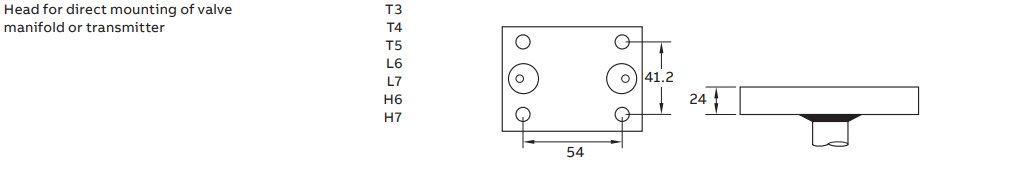

End Support Options:

- Threaded End Support

- Flanged End Support

- Weld Cup End Support

- Gear Retract Mechanism for hot-tap models

Process Isolation Valves:

- Sizes: 1/2 in., 3/4 in., 1 in., 1.5 in., 2 in., 3 in.

- Material Options: 316SS, Alloy 400, Alloy C276

- Pressure Ratings: Up to 100 bar (1450 psi)

Temperature Elements (Optional):

- Integral PT100 sensor, neck-mounted (4-20 mA output)

- Integral Type K thermocouple sensor

- Pressure Rating: Up to 70 bar (1015 psi)

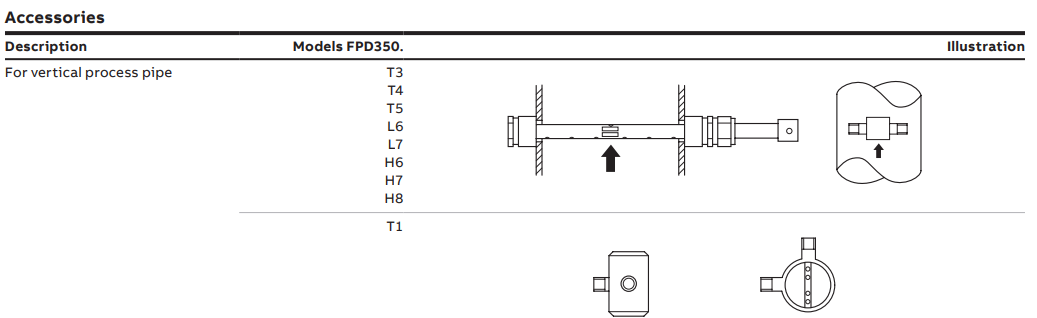

Additional Accessories:

- Air Eliminators

- Condensate Pots (Carbon Steel or 316SS)

- Frequency Collars

- Gear Retraction Assemblies

- Bi-directional Probe Configuration

Certifications and Compliance:

- EN 10204 3.1 / 3.2 Material Certificates

- NACE MR 0175/ISO 15156 for corrosion resistance

- Pressure Testing and Positive Material Identification (PMI)

- Radiography and Dye Penetrant Inspection (DPI)

Electrical Output Options:

- Analog Output: 4-20 mA, 2-wire

- Alarm Signaling: Min/Max Alarm Units

- Electrical Connections: NPT or BSPT, cable lengths available upon request

Installation Orientation:

- Horizontal or vertical installation

- Compatible with circular and rectangular pipes/ducts

Special Options:

- Partial Insertion Probe

- Gear Retract for Hot-Tap Applications

- Special Neck Lengths and Custom Fittings

Supporting Documents

Technical documentation (FPD350 averaging pitot tube) provides specifics on probe types and installation guidelines.

Industries & Solutions :

Used in many flow monitoring scenarios such as plant steam flow, furnace air intake, ventilation exhaust, and large-scale cooling or heating loops. Particularly beneficial in retrofits or space-constrained installations, since it imposes a very small pressure drop and tolerates flow disturbances better than single-point sensors.

- Manufacturing and assembly lines

- Water and steam utilities

- Food and beverage process control

- Mid-scale chemical and blending facilities

- ESG and plant-level environmental reporting

Tools and Resources

Dedicated selection tools and calculators (often provided by the manufacturer) facilitate model selection and predict differential pressure outputs for given fluid properties.