Solutions

Solution

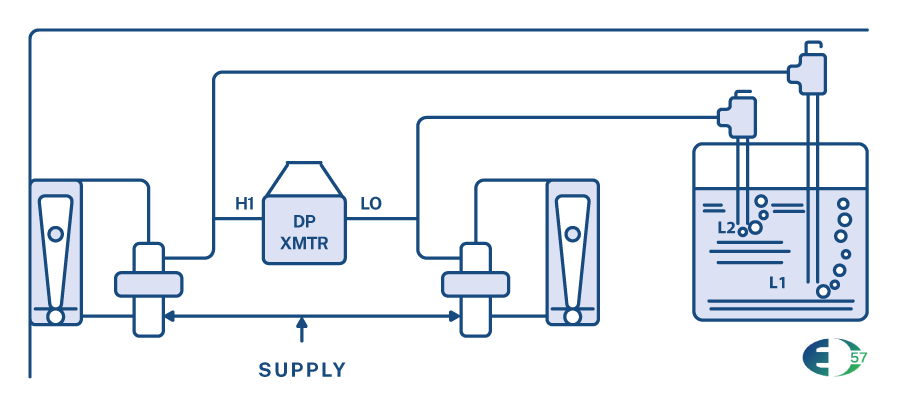

Density of liquid in a tank can easily be measured by using two Bubble Tubes inserted to two different depths both continuously submerged. The difference in back pressures of the purge gas in the two bubble tubes is a function of the density and the difference in the depth of the two tubes.

Solution

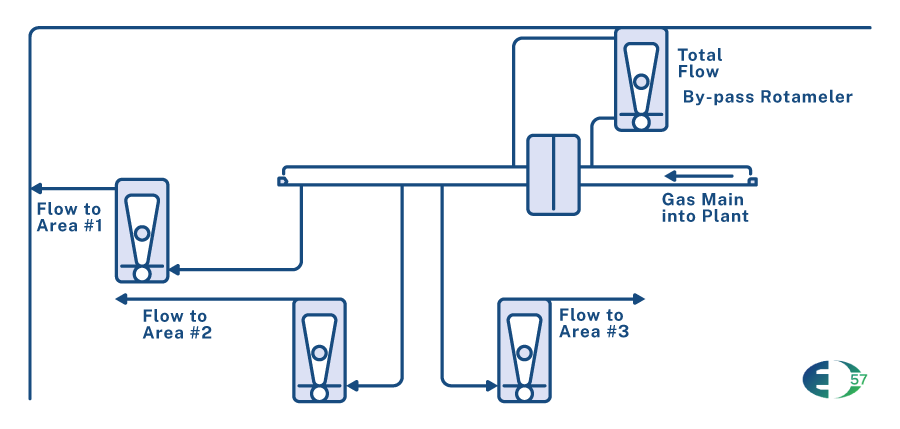

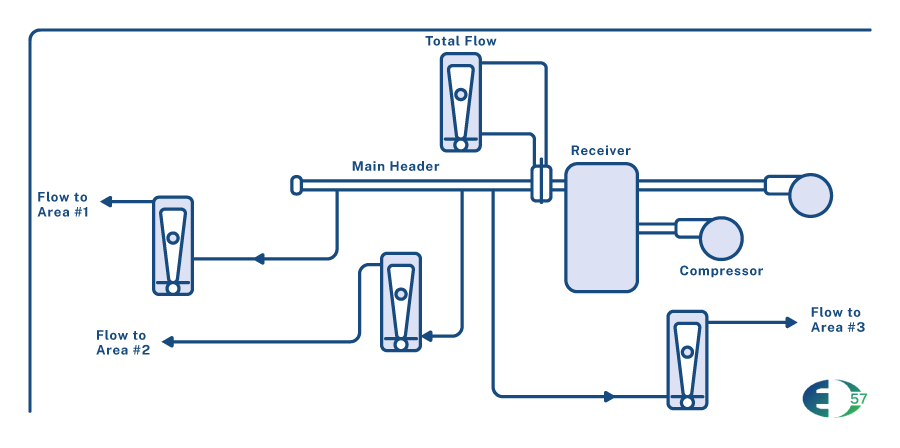

Plants that use large amounts of gaseous fuel, mostly Natural Gas, are constantly searching for ways to conserve energy, especially each time there is an increase in gas prices. In order to evaluate where efficiencies can be realized and gas saved, it is necessary to obtain usage figures (flow rates) for all areas or major users in the plant.

Solution

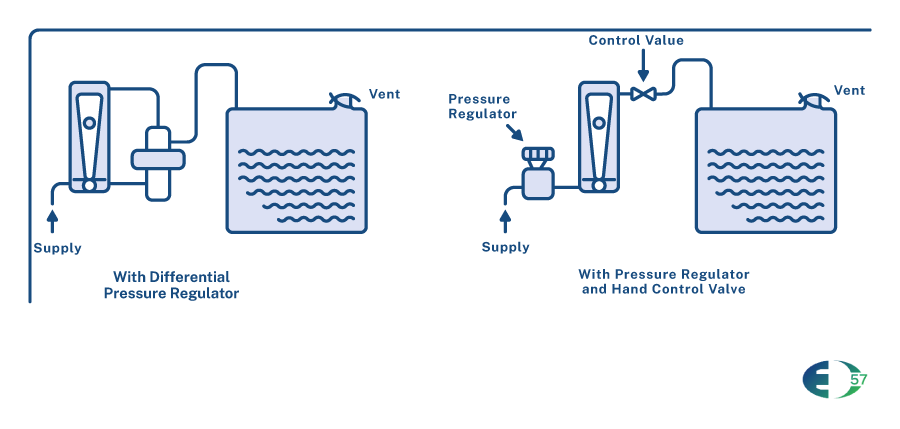

Many liquids in the Chemical and Food & Beverage industry must be protected from contact with air. The oxygen in air can cause oxidation, resulting in unacceptable consequences ranging from discoloration or spoilage to catastrophic explosion. A blanket of an inert gas introduced through purging of the tank or vessel, protects the liquid from contact with air.

Solution

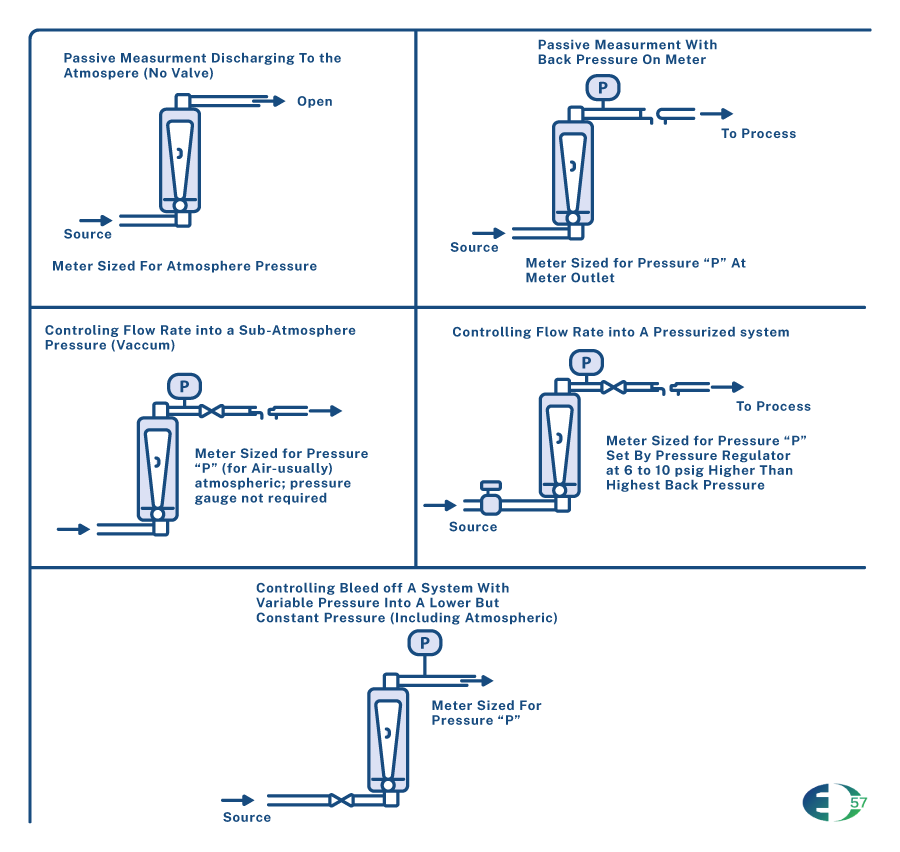

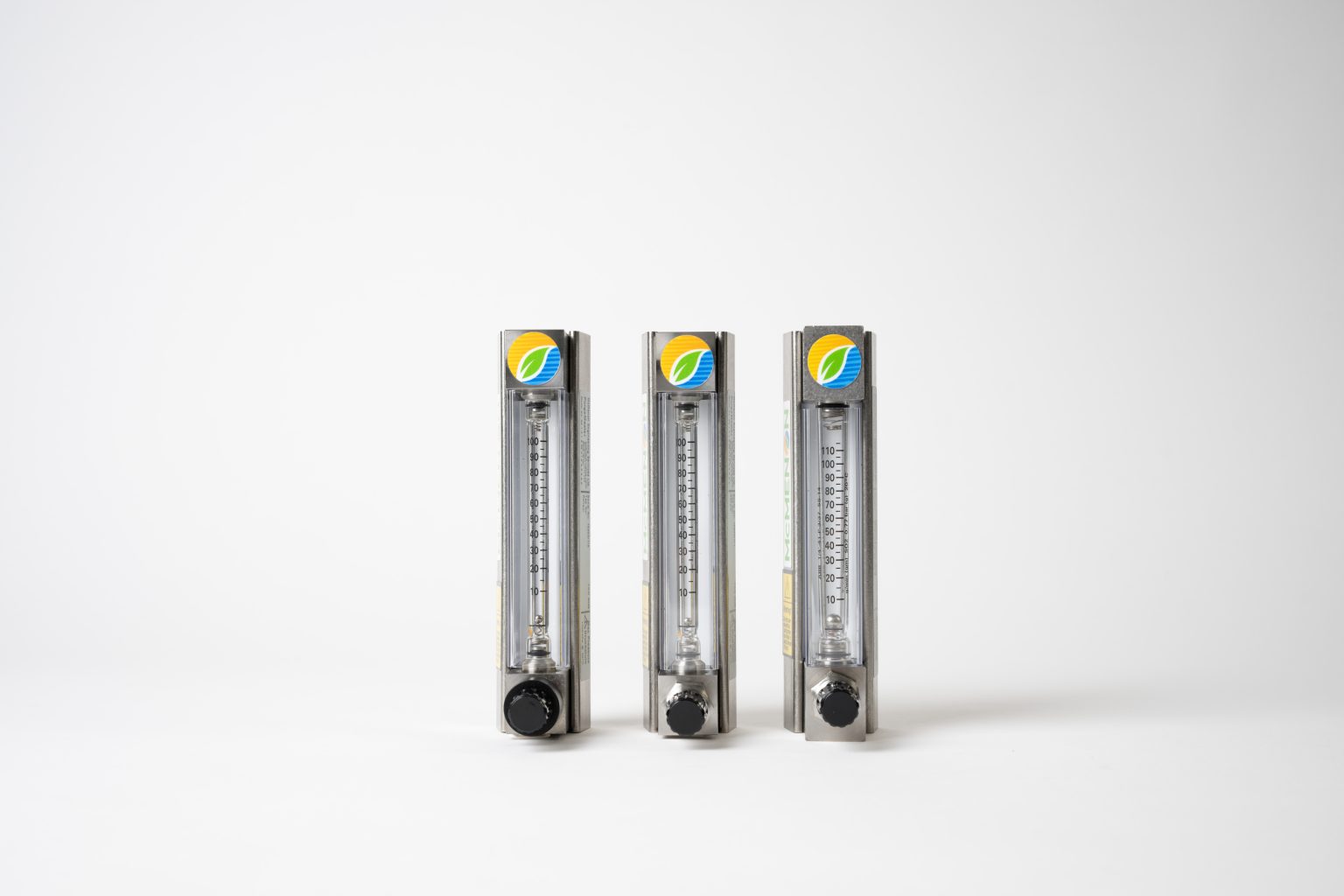

Rotameters are far and away the least expensive flowmeters for gas flow rate applications. However, many users or potential users are not well versed in the technology involving the relationships between flow rate, static pressure and pressure drop for compressible fluids (gases). Nor are they aware that gas temperatures and pressures affect rotameter readings (and sizing) because of the effect on gas density.

Solution

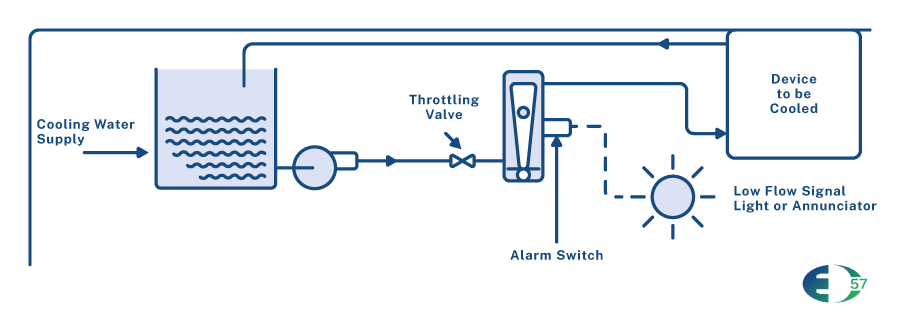

Certain types of electrical equipment, especially those that operate under high power loads or within enclosed spaces, generate significant amounts of heat during normal operation. To prevent overheating and the associated risk of thermal damage to internal components, these systems often require continuous cooling. This is typically achieved through the constant circulation of cooling water, which absorbs and carries away excess heat, thereby helping to maintain safe operating temperatures and ensure the reliability and longevity of the equipment

Solution

Compressed air is used in most plants, in a broad range of industries. Since like a utility, it is used throughout most plants there is a potential for a large amount of wasteful use and leakage due to aging piping and equipment. Plant Managers or Energy Conservation Specialists have a need to monitor usage in various departments and at different times of day and night.

Solution

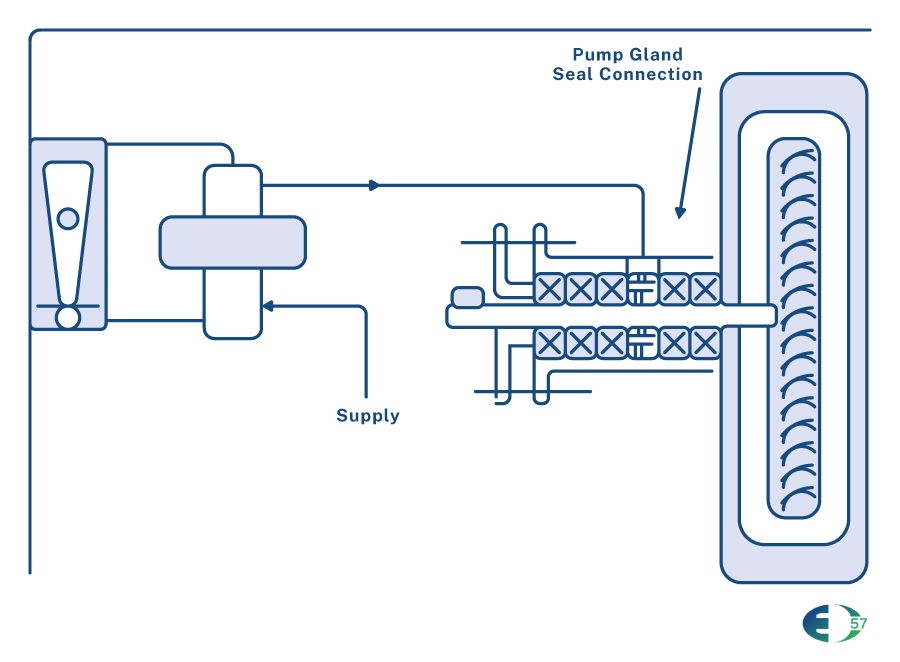

Many pumps designed for use on corrosive or toxic liquids are equipped with a pump gland seal connection into which a small flow rate of a harmless liquid is continually forced. The seal liquid is forced past the inboard sealing rings into the impeller chamber. Any leakage past the outboard sealing rings is the harmless seal liquid.

Solution

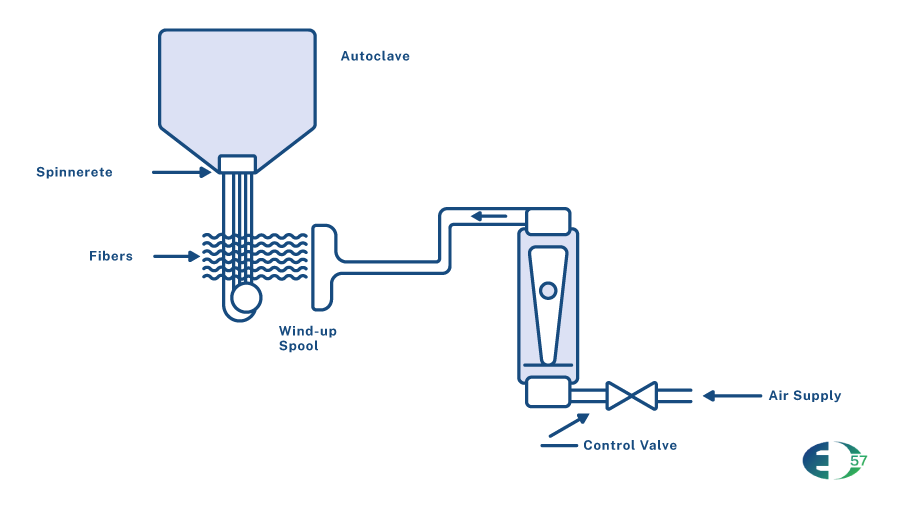

Melt spun fibers such as Nylon and Polyester are formed by extruding the very hot liquid polymer through spinnerets with hundreds of very small orifices. The polymer cools as it drops vertically downward from the overhead spinneret. To accelerate cooling and solidification of the polymer, air is blown horizontally through the bundle of fibers. The rate of air flow, being critical, is set and monitored to ensure that it is completely cooled and solidified before reaching the wind-up spool.

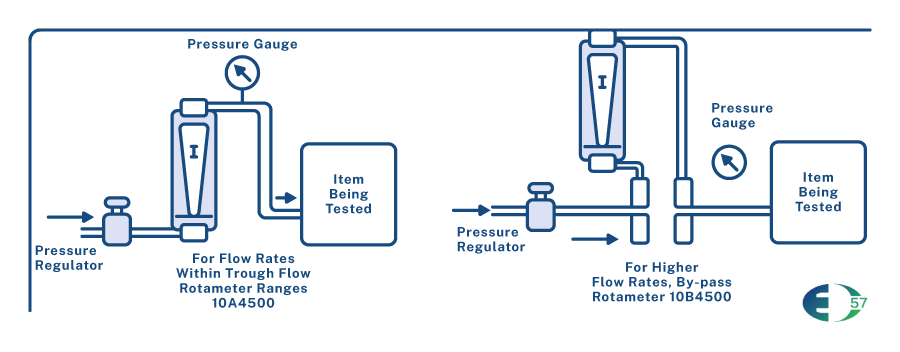

Service

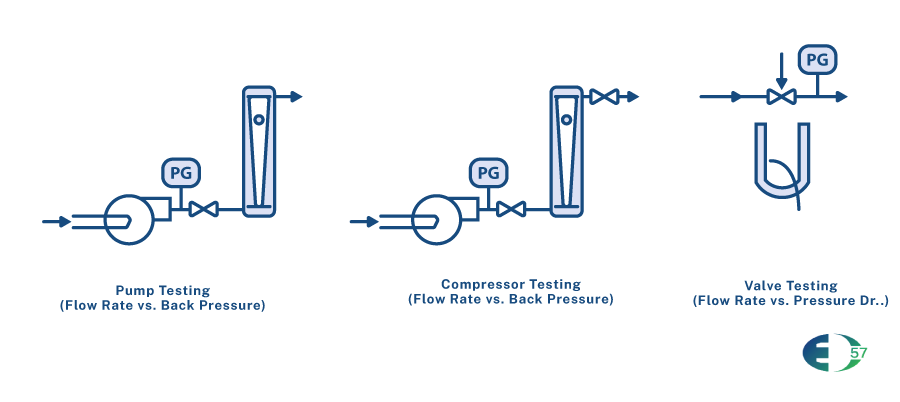

Manufacturers of pumps, compressors, and valves require flowmeters for research, prototype testing, and finished product qualification and inspection.

Service

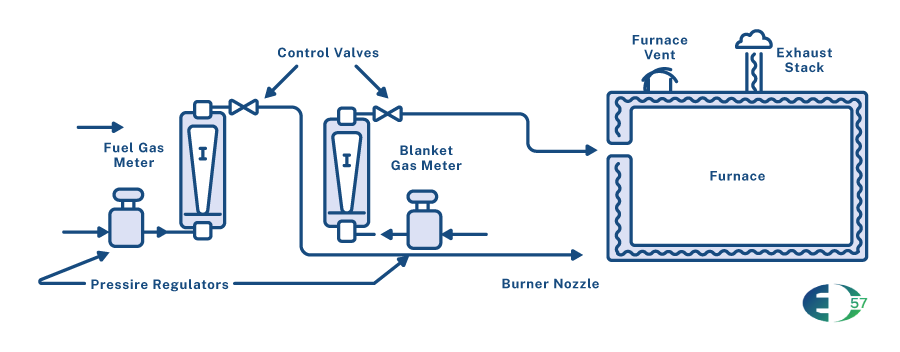

Most heat treating and annealing ovens are gas-fired with natural gas, propane, or manufacturers’ gas. Many heat treatment processes require the introduction of one or more other gases to modify the internal atmosphere of the furnace during the treatment process. Since the temperature in the furnace and the composition of the “Blanket” gas are critical, the flow rate of all gases must be controlled.

Service

There are many types of gas analyzers, all of which require the measurement and/or controlling of low rates of gas for sampling and introduction of modifying gases.

Service

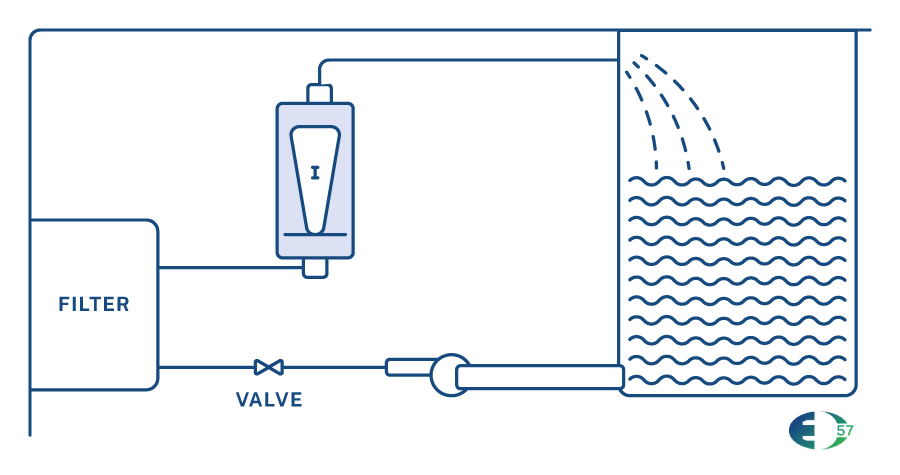

Industrial Washers, degreasers, ultrasonic cleaning machines, etc. generally require the setting and monitoring of the cleaning liquid being recirculated through the filtration system. Rotameters provide the most economical and most user-friendly means of doing so.

Service

A wide range of products require that the air leakage in (or out) be limited to a practical (or statutory) level.

Leakage measurements require the measurement of air flows for R&D, manufacturing inspection and qualification testing.

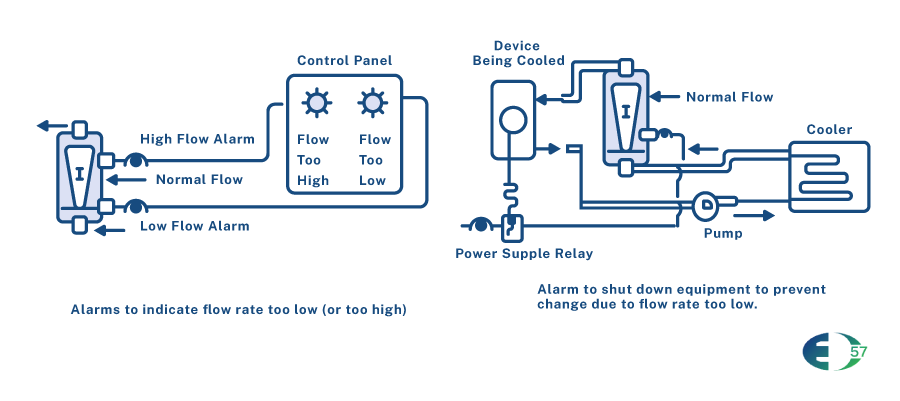

Service

Many flow measurement applications require an automatic signal generated in the event of a drop in flow below the desired rate or an increase above the desired rate. This signal is then used to signal an alarm in the form of a warning light or audible alarm or to provide automatic switchover or system shutdown.