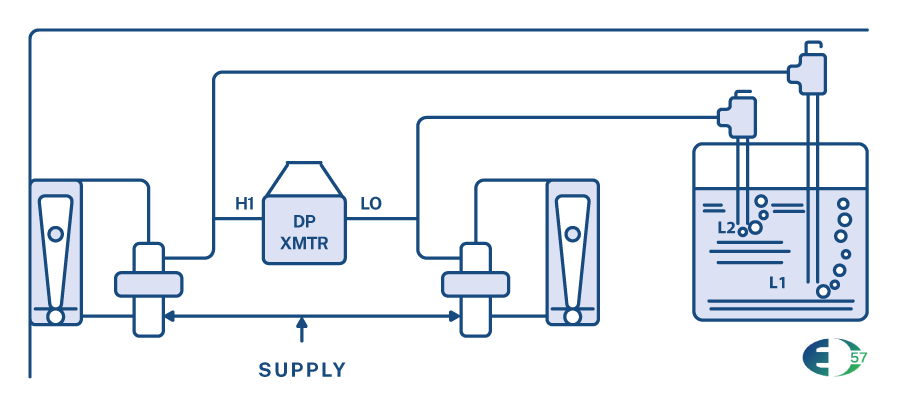

Description of Application

Density of liquid in a tank can easily be measured by using two Bubble Tubes inserted to two different depths both continuously submerged. The difference in back pressures of the purge gas in the two bubble tubes is a function of the density and the difference in the depth of the two tubes.

Used Where?

- Chemical Companies

- Pulp & Paper Companies

- Petroleum & Petrochemical Companies

Method of Operation

A small, but uninterrupted flow of air (or inert gas such as Nitrogen) is easily set, controlled and monitored by the use of a purge type Rotameter. The flow rate must be low enough to ensure that no increase in head back pressure occurs due to pressure drop through the purge piping and dip tubes. The flow should be continuous and not interrupted or the back pressure may decrease below that of the process fluid head which would give an incorrect level reading and possibly allow the process liquid to reflux back to the purgemeter and the D/P transmitter. Note that controlling the exact flow rate is not critical, but that the flow rate must be low and uninterrupted. The purge gas supply pressure must exceed the static pressure at the bottom of the longer dip tube by about 10 psi.

Model Selection

Use Purgemaster Model FAM3200. For most applications the standard 2 SCFH air capacity is suitable. An alternate method is to use FAM3200 with a pressure regulator on the supply side. The fittings may be brass for air or inert gas, but stainless steel may be preferred by the customer. For pressures above 250 psig use Model FAM3200.

Used How?