Compressed Air Monitoring

Description of Application

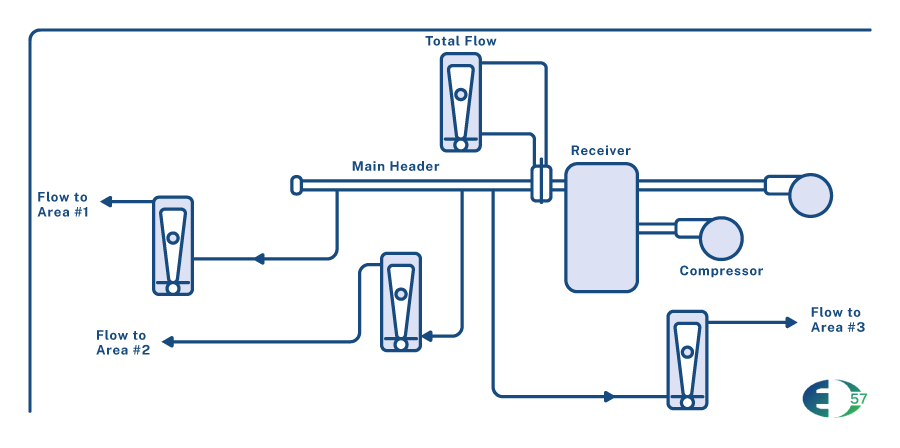

Compressed air is used in most plants, in a broad range of industries. Since like a utility, it is used throughout most plants there is a potential for a large amount of wasteful use and leakage due to aging piping and equipment. Plant Managers or Energy Conservation Specialists have a need to monitor usage in various departments and at different times of day and night.

Used Where?

- Manufacturing

- Petrochemicals

- Food and Beverage

- Chemicals

- Pulp and Paper

- Metals and Mining

Method of Operation

Through-flow Rotameters or By-pass Rotameters can be used depending on flow rates. A permanent rotameter installation in each line affords easy monitoring of all flows at any time. If the gas flows are high enough and are to be checked infrequently (annually), it is possible to install an orifice plate in each line with a 1/2″ ball or gate valve on the orifice pressure taps and to use one meter to obtain the flow rates by connecting the meter to each set of orifice tap lines in turn. The meter scale must be graduated for the average line pressure and the readings corrected for pressure if it varies.

Model Selection

Glass Tube: Use FAM4555 for lower flow rates and FAM5555 for rates above those of FAM4555.

Metal Tube: FAM54371 for Indicator or FAM54331 for transmitting the flow to a central location.

Use brass fittings in FAM4555 & FAM555; use stainless steel tube and fittings in FAM541.

Installed How?