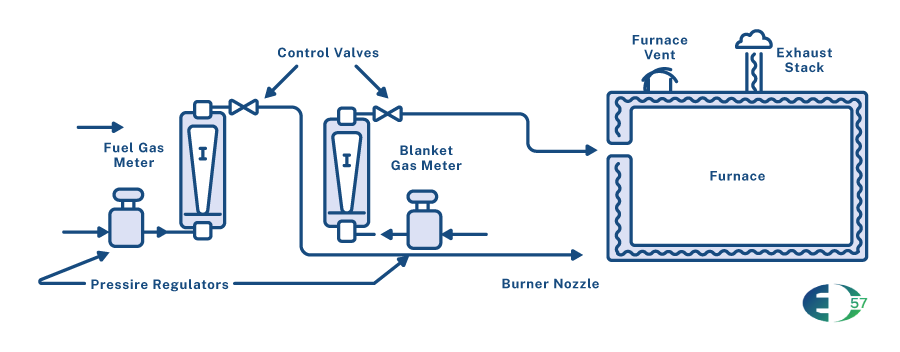

Gas Flow To Heat Treating Furnaces

Description of Application

Most heat treating and annealing ovens are gas-fired with natural gas, propane, or manufacturers’ gas. Many heat treatment processes require the introduction of one or more other gases to modify the internal atmosphere of the furnace during the treatment process. Since the temperature in the furnace and the composition of the “Blanket” gas are critical, the flow rate of all gases must be controlled.

Used Where?

- Large manufacturers with their own in-house treatment process

- Small Local Heat Treatment Shops

- OEMs that manufacture a line of heat treatment equipment

- Metallurgical Labs

Rotameter Solution

Nearly all such applications are at low pressures, at or slightly over atmospheric. Indicating-only rotameters are ideal for this application since they are accurate, easy to read, have low pressure drops, and are the least expensive type of flowmeter.

Model Selection

Model FAM54 is the model of choice for this application. End fitting and O-ring material selection is dependent on the type of gas.

Method of Operation

The fuel gas flow and blanket gas(es) flow, when required, are set and controlled manually by the operator using the pressure regulators and control valves. Since most furnaces operate at atmospheric pressure, gas flows are nearly always near a pressure of 14.7 psia. It is necessary to supply a meter that has a low pressure drop and a “minimum PSIA” of under 14.7 psia.

Installed How?