Melt Spun Synthetic Fiber Quenching Air Flow

Description of Application

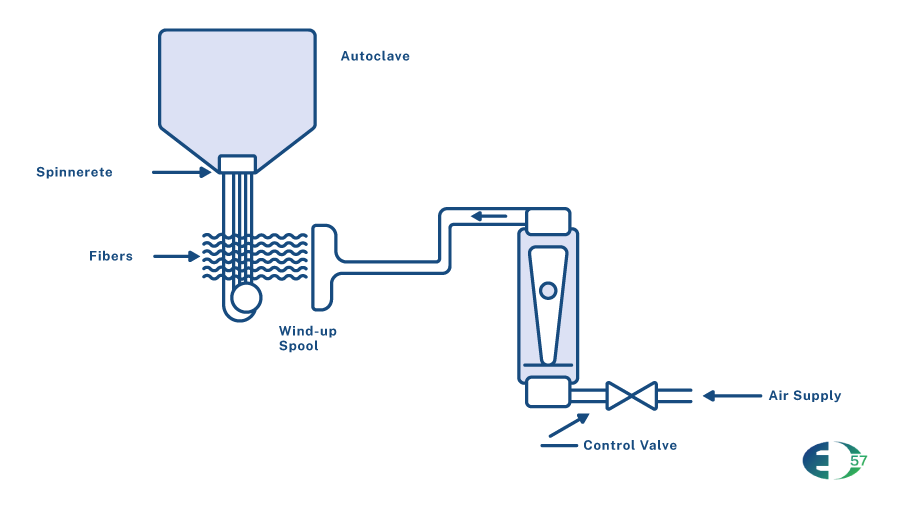

Melt spun fibers such as Nylon and Polyester are formed by extruding the very hot liquid polymer through spinnerets with hundreds of very small orifices. The polymer cools as it drops vertically downward from the overhead spinneret. To accelerate cooling and solidification of the polymer, air is blown horizontally through the bundle of fibers. The rate of air flow, being critical, is set and monitored to ensure that it is completely cooled and solidified before reaching the wind-up spool.

Used Where?

- Companies Manufacturing Nylon or Polyester Fiber

Method of Operation

The operator must set the quench air supply for optimum results depending on the ambient air temperature, the diameter of the individual fibers, and the speed of the fibers from spinneret to wind-up spool.

Model Selection

The most widely used type of meter for this application is the glass tube type meter with 10″ scale length. Use Model FAM4555.

Rotameter Solution

Large size Rotameters provide the lowest installed cost for measuring high flow rates of gas at low pressures. The excellent scale resolution, readability and repeatability are also important factors.

Installed How?