Description of Application

Many liquids in the Chemical and Food & Beverage industry must be protected from contact with air. The oxygen in air can cause oxidation, resulting in unacceptable consequences ranging from discoloration or spoilage to catastrophic explosion. A blanket of an inert gas introduced through purging of the tank or vessel, protects the liquid from contact with air.

Used Where?

- Chemical Companies

- Petroleum & Petrochemical Companies

Method of Operation

When a liquid in a tank cannot come in contact with air, a tank purge system fills the tank with the purge gas, excluding all air. The liquid is then introduced and in continuous process systems air cannot re-enter the tank because of continuous venting of the purge gas. The rate of flow of the purge gas is dependent on the size of the tank and the size of its vent(s). For small and relatively “tight” tanks purgemeter flows are usually adequate. For large tanks and/or those with larger vent areas, larger flow meters may be required.

Model Selection

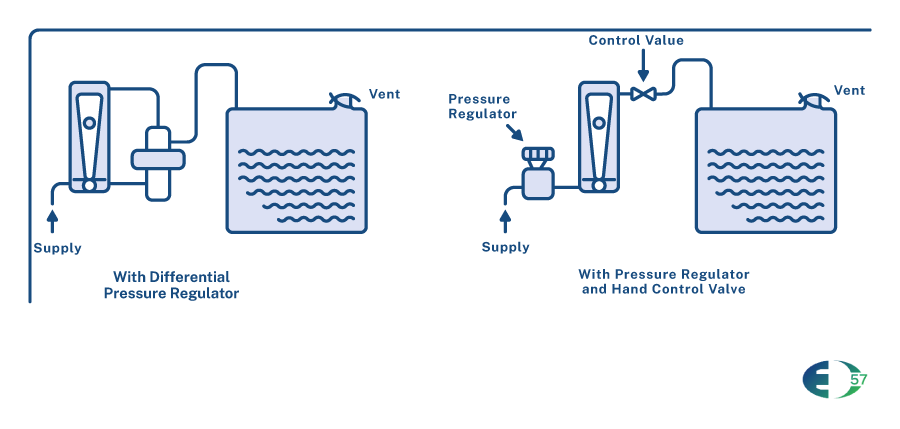

A6100/A6200 series – with a Differential Pressure Flow Controller for low flow rates

A6100 series – used with a pressure regulator – for higher flow rates

A6100 series – and control valve

Used How?